Carbide Cutting Services

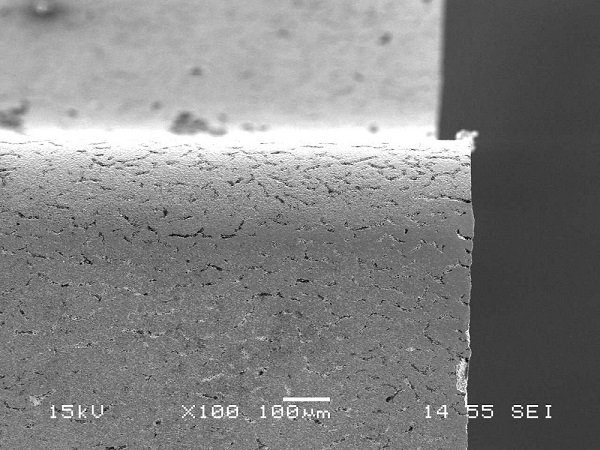

Carbide is held together by binders. Improper processing can leach those binders and cause premature failure. Figure 1 (below) is magnified 100x and shows binder degradation that would be prone to chipping and premature failure due to improper WEDM methods.

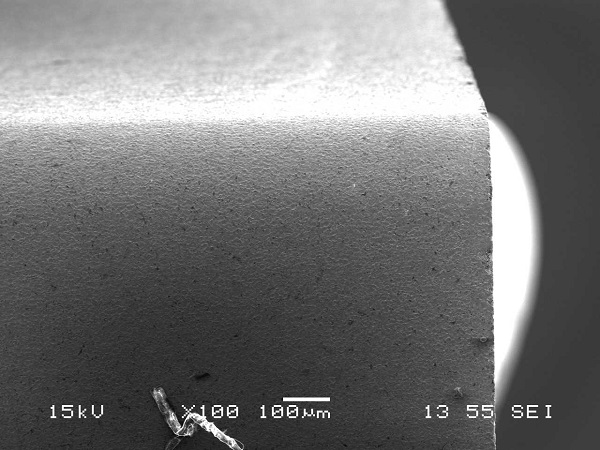

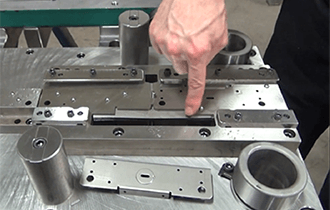

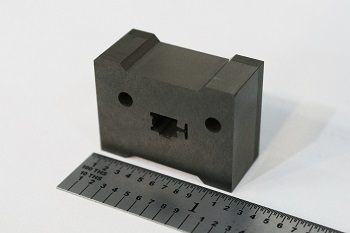

We have developed an expertise in supplying custom shape carbide punches and inserts for stamping dies. Figure 2 (below) shows a much more solid grain structure that should result in a superior high volume stamping punch with the binders still intact. Processing for Figure 2 employed our best practices, including the purity of our WEDM water, limiting contaminants in the machines and other post WEDM processes required to prevent damage to the material binders.

Surface finish is also important. Our Agie WEDM machines are capable of creating surface finishes as fine as 4Ra”. Cut edge surface finish also comes into play when sharpening carbide on a surface grinder. Poor selections of grinding media and coolants can damage the structure of the carbide and lead to premature cut edge failure.

When properly processed, carbide can add to your bottom line. Our WEDM department is here to help you find success. Agie Wire EDM excels at cutting precision carbide and tool steels. Send us your information and let’s see how we can serve you today.

Tolerances held to +/-.00005” in a climate controlled atmosphere for machining and inspection. Surface finishes as fine as 4Ra” in carbide and 8Ra” in tool steels. We have a full service tool room to assist with any prep or secondary finishing needed. See our CNC Surface & Form Grinder. We are here to assist you with overflow, component work or production Wire EDM services. Our lead times in WEDM are often days, not weeks.

At Wisconsin Metal Parts we welcome challenges!

Frequently Asked Questions about Carbide Cutting

Lead times for carbide will depend on the type of carbide needed and if there needs to be any tapped holes in the material. Typically, a standard carbide component without tapped holes can be processed in a matter of a few days. With tapped holes might take 2-4 weeks due to the raw material lead time.

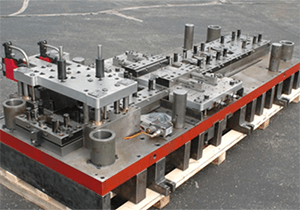

We have 4 Agie wire EDM machines that are specifically designed to cut carbide. Carbide does not cut much differently than tool steel in the wire machine but there are specific processes that need to be followed to insure the integrity of the carbide material remains intact.

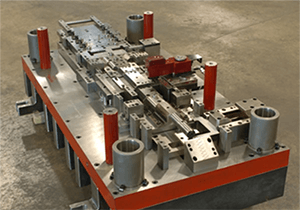

We have found that properly processed carbide punches and die inserts can increase progressive stamping die runs by 2-3x what tool steel components can produce between sharpening’s. In most cases carbide has a great ROI for high volume metal stamping and is worth the investment. The next question is if your tooling and press equipment is robust enough to support carbide tooling.

We can hold finishes as fine as 4 Ra” in carbide and 8 Ra” in tool steel.

Typically we can hold tolerances as tight as +/-.00005” in our climate controlled atmosphere for machining and inspection.

We do not supply round or catalog style carbide components. We provide custom punch and die insert shapes using Wire EDM or surface/form grinding. Check out our CNC Surface & Form grinder

Photo Gallery

Photo Gallery Capabilities

Capabilities Videos

Videos Quality Management

Quality Management