Metal Stamping Services

What is Metal Stamping?

Metal stamping involves converting flat sheet metal into specific shapes. It uses a variety of metal forming techniques including blanking, punching, bending and piercing. It is a fast and cost-effective solution for high-quantity manufacturing. The process involves a stamping die, made custom for the specific part that is being manufactured. Once the initial cost and time to develop the tooling is complete, the versatility of stamping allows a manufacturer to run high volumes of a unique piece in very little time at a lower price. Progressive dies are a popular choice of tooling, and you can learn more about these dies from this video here.

What can we do for you?

Wisconsin Metal Parts, Inc. provides metal stamping services to a variety of industries. We run stampings up to .250” thick, but our specialty is high-volume, tight tolerance, precision stampings in a variety of materials from .003”-.060” thick. Our presses have full feed lines and are die sensor protection ready. We run nearly 60 million metal stampings per year at a 98% on time delivery rate.

Take your production needs to the next level without sacrificing quality. With CNC Machining, Fabrication, CNC Grinding, Wire EDM and support operations, WMPI can be a single source for your assembly and sub-assembly projects.

Wisconsin Metal Parts, Inc. is ISO 9001:2015 certified. To learn more about our metal stamping services Contact us today or see the links below.

Custom Metal Stamping

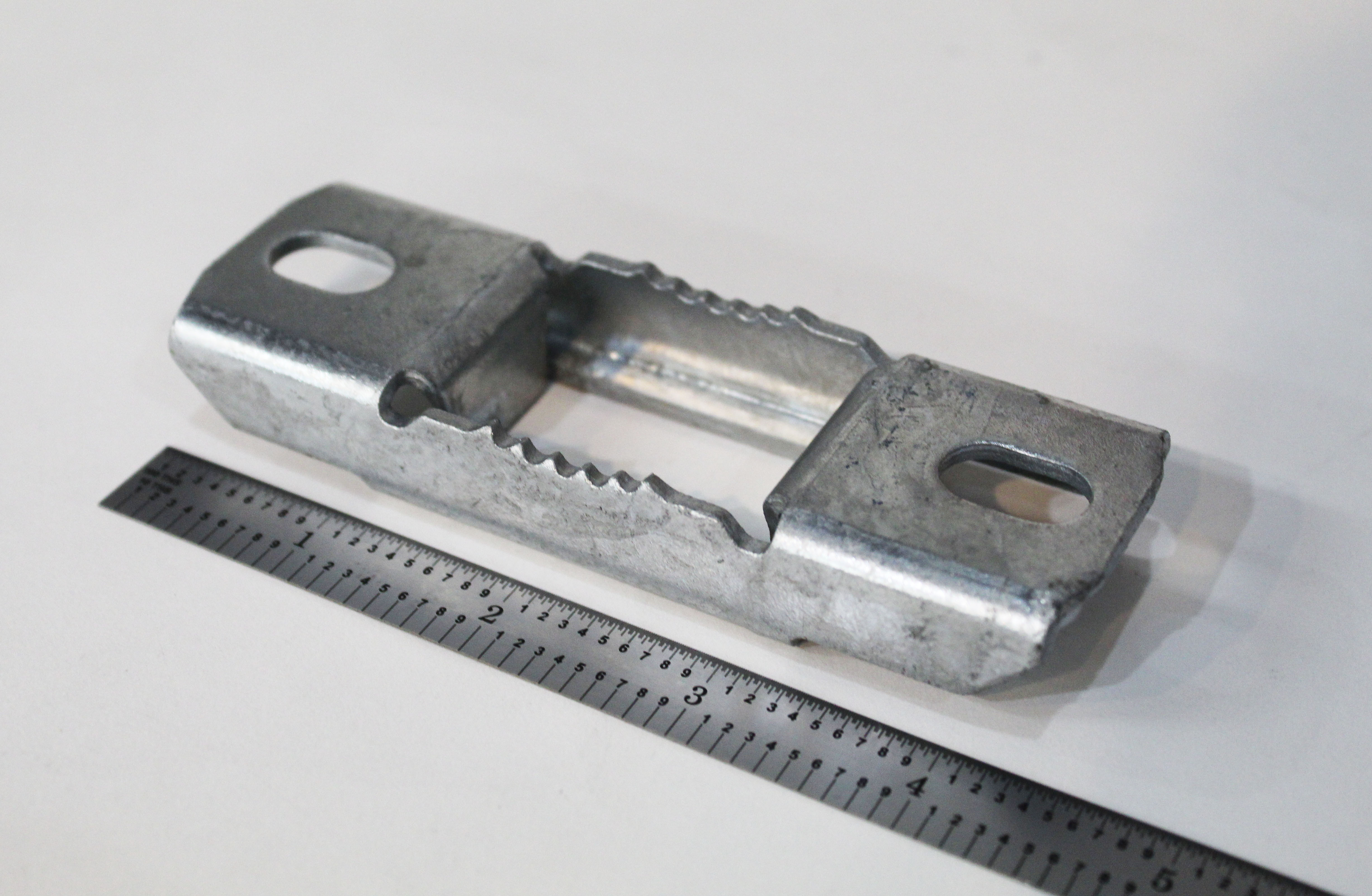

Whether you are looking for metal stamping parts and components to supplement other tools and equipment, or you need an independent part altogether, our team has the depth of experience necessary to ensure custom metal stamping to serve your unique needs. Our customers benefit from in-house production metal stamping capabilities for custom tooling, gage and fixture building.

Low Volume Metal Stamping

Many of our customers face the ongoing dilemma of high tooling costs for a smaller volume of parts that require metal stamping. Our experienced engineers will evaluate material tolerances, assess the level of accuracy required, and take into account all the critical factors before recommending the best alternative for low volume metal stampings.

High Volume Metal Stamping

If your company is needing more than a million metal stampings run annually, we may need to step up our tooling and process plan to insure consistent quality. How will you manage efficient production runs, optimize your tooling, keep your quality consistently high, and your costs low? Our team has the knowledge and experience you can trust to help you achieve these goals.

Precision Metal Stamping

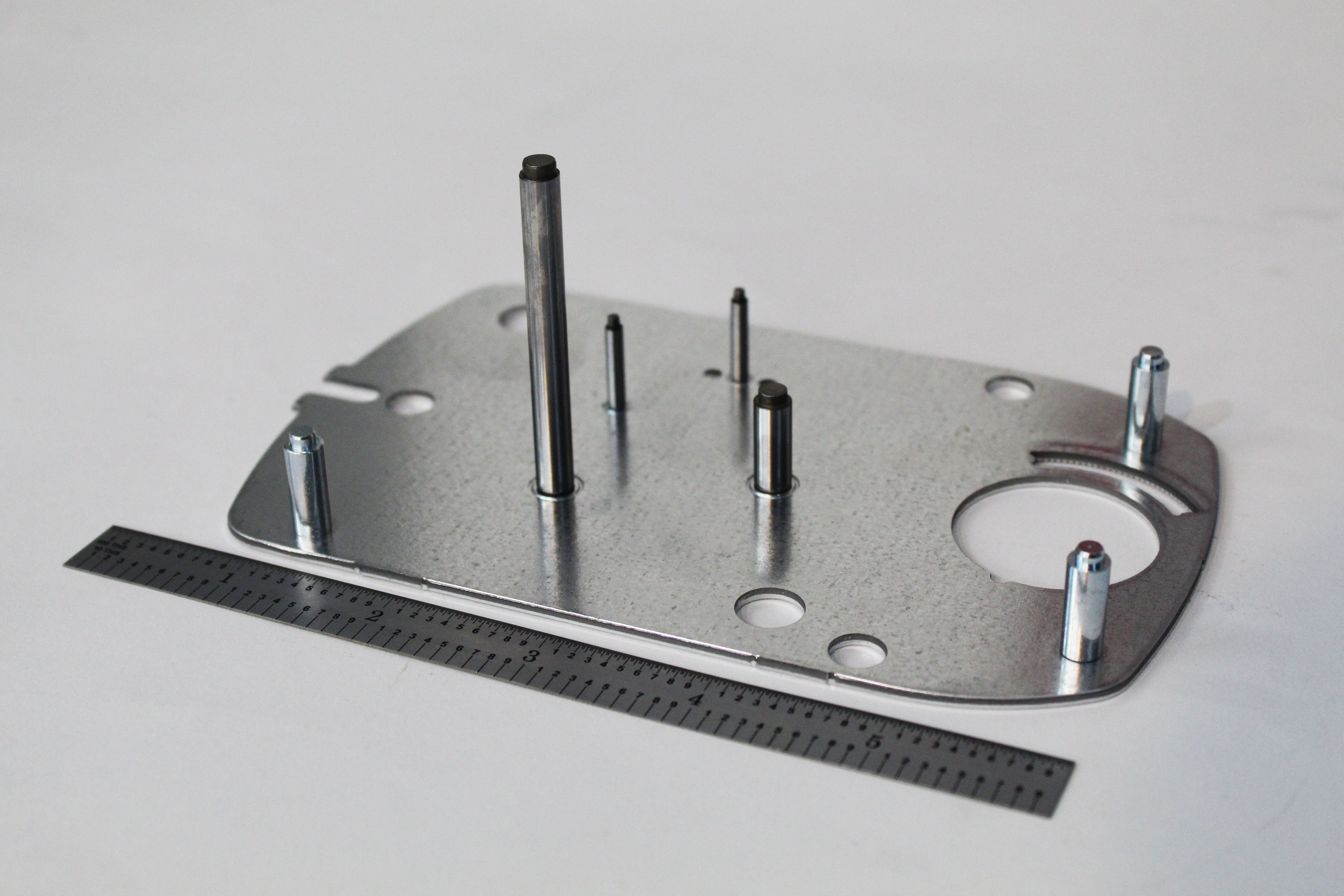

With years of experience and advanced capabilities, our engineers ensure that you get the design flexibility, speed of manufacturing, and cost efficiencies you need for your precision metal stamping. We have state-of-the-art equipment and a range of resources at your disposal to help accomplish your metal stamping projects from prototyping through to production.

Frequently Asked Questions about Metal Stamping

We can work with any type of metal: aluminum, steel, stainless steel, bronze, copper, brass, phosphorous bronze, kovar, Inconel, beryllium copper and clad material to name a few. Our preference is coil, and we can run strip stock if necessary

96 inches, our largest bed is 33” x 96”

200-tons

From square one, if we have to build tooling and PPAP, it can be 4-20 weeks depending on the complexity of the part, tool and gaging. Production orders are largely dependent on material availability. Blanket orders sometime allow us to lock in material pricing and have material delivered just in time to run.

For production stamping we often find orders up to 30,000 might be more cost effective to run in one of our fiber lasers and then use a combination of brake press or secondary forming tooling in a punch press. This approach can potentially save you thousands of dollars in up-front tooling. We can work with you to find the production method that is most cost-effective for your application. It really depends on the part, tolerances and what the anticipated future volumes might be.

For a punched hole .0005 inch

Forming tolerances depend on the material, thickness and complexity. Send us your part drawings and we can give a better estimate

Our 30-ton Bruderer can run up to 600 strokes a minute, with a mechanical feeder. Our presses range from potential single stroke operations up to 600 strokes per minute on the Bruderer, most of our presses have variable speed drivers to adjust for each specific application

Our feeders can handle material up to 16 inches wide and ¼ inch thick. Our tonnage limit is 200-tons. The tonnage is the real deciding factor and would need to be calculated based off your part print.

Yes, we do! We design in 3-D using Solidworks and a LogoPress add-on that allows us to quickly put together a strip layout concept for quoting. We also have simulation software that assists us in finding trouble spots in the forming operations. This often allows us to reduce development time and pass along the benefits of shorter lead times and competitive tooling costs.

How small do you need?

We run almost 60 million stampings a year from our facilities, so anywhere from 100,000 and upwards is ideal but again this depends on the size and complexity of the part. We see each job as an individual so lets take a look at what you have and see how we can help.

Short answer: No. One of the advantages of metal stamping is that you can produce thousands, even millions of identical products with an extremely small margin for error and imperfections. A well built and maintained tool will bring you consistency in the part run. A solid Quality Program will insure only conforming parts are being shipped. Thanks to our in-house tooling, gage and fixture building service, as well as rigorous inspections and data collection, our volume of output will never be at the expense of quality. Whether you need a few prototypes or millions of parts, you can trust that you will receive the same consistently high quality.

After the initial tooling investment, production stamping is usually your most cost-effective solution for volume part runs. Our tools and presses are equipped with sensors that allow tooling to run minimally attended while still delivering on quality.

Every job is different from the last. Our expert team of experienced engineers, designers and tool makers will work with you throughout the manufacturing process to help make sure you get the result you are looking for. If you bring us in early enough, we can even make design recommendations or other suggestions to help troubleshoot issues and advise on material choices.

Wisconsin Metal Parts Inc. is capable of accommodating a wide variety of metal stamping methods for getting the job done. Here are the types of stamping we offer: prototype stampings, production metal stamping, high-speed metal stamping, precision metal stamping, progressive die stamping; high quality, complex, tight tolerance stamping; low-volume prototypes to high-volume progressive dies; taking over existing stamping projects from other companies.

We can do FAIR, PPAP or any other part qualification process you may have. We also have the ability to Lot control parts through production & subcontracting until they get shipped to you. We have traceability on material, subcontracting and can provide certifications. We can manage every detail about the parts and processes up until they are received by our customers.

For production stamping you will need tooling, and there are a wide variety of options. Some of these include building traditional hard tooling, progressive dies or single hit dies. For lower volumes we have the option to cut blanks in our fiber lasers and perform secondary forming in a brake press or punch press. If you are paying for the tooling then you would own it. If the opportunity is right, we can also discuss other tooling and financing options. Normal tooling maintenance is usually included in our piece part price so you will not have hidden costs coming at you later. As tooling components reach their useable life and need to be replaced, we will give a cost estimate and discuss how to proceed at that time.

If you own tooling and have it with another supplier, we would be happy to hear about your challenges and discuss the options available to do a smooth takeover and continue delivering your production parts.

How robust of a tool we build depends on several factors including; anticipated volumes, your tooling standards, complexity of the part and your budget. There are other factors that can come in to play but these are some of the main drivers. Higher volume tooling will normally be built with interchangeable wear items that can be replaced in the future. See our link to “What Makes Up A Progressive Die”.