Heat Transfer Industry Production Cells

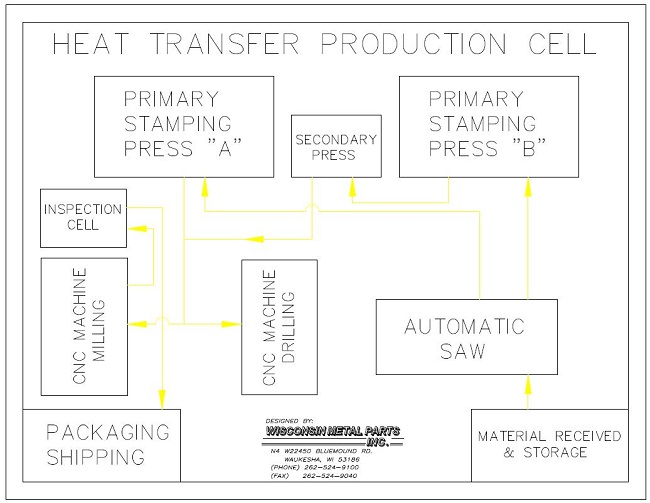

Detailed and complicated parts are never a problem for the skilled staff at Wisconsin Metal. Our customer got us involved early in this project and we helped develop this Heat Transfer part all the way from prototype through production. When approached to fabricate this heat transfer part, we knew we could build the necessary tooling and fixturing. Made from aluminum, we applied stamping, CNC machining, manual milling, and CNC sawing to produce over 100 configurations of slots, holes, and lengths called for on the 2D CAD drawing. The tubes were of variable lengths up to 48”. Manufacturing of these tubes required a contaminant-free environment and we maintained manufacturing tolerances to ±.005” throughout the process. The finished tubes were also specially packaged to prevent contamination. Wisconsin Metal Parts is capable of handling difficult or intricate parts that require multiple forms of production.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description | This product is used within a(n) heat transfer application. There are over 100 configurations of slots, holes and lengths that tooling and fixturing was built to accommodate. Raw material is tracked and controlled per the individual part families and is rotated using the oldest material first. This is a contaminant free environment for production and storage. | ||

| Capabilities Applied/Processes |

|

||

| Equipment Used to Manufacture Part |

|

||

| Overall Part Dimensions |

|

||

| Tightest Tolerances | +/-.005" | ||

| Material Used | Aluminum tubing | ||

| Max Material Finish | #4 Brush with vinyl | ||

| In Process Testing/Inspection Performed |

|

||

| Industry for Use | Heat Transfer | ||

| Volume | 500,000 pieces EAU Weekly shipments |

||

| Delivery Location | Midwest, USA | ||

| Standards Met | Customer supplied print, 2D CAD Drawing Customer internal specifications. Returnable packaging. |

||

| Product Name | Heat Transfer Tube |