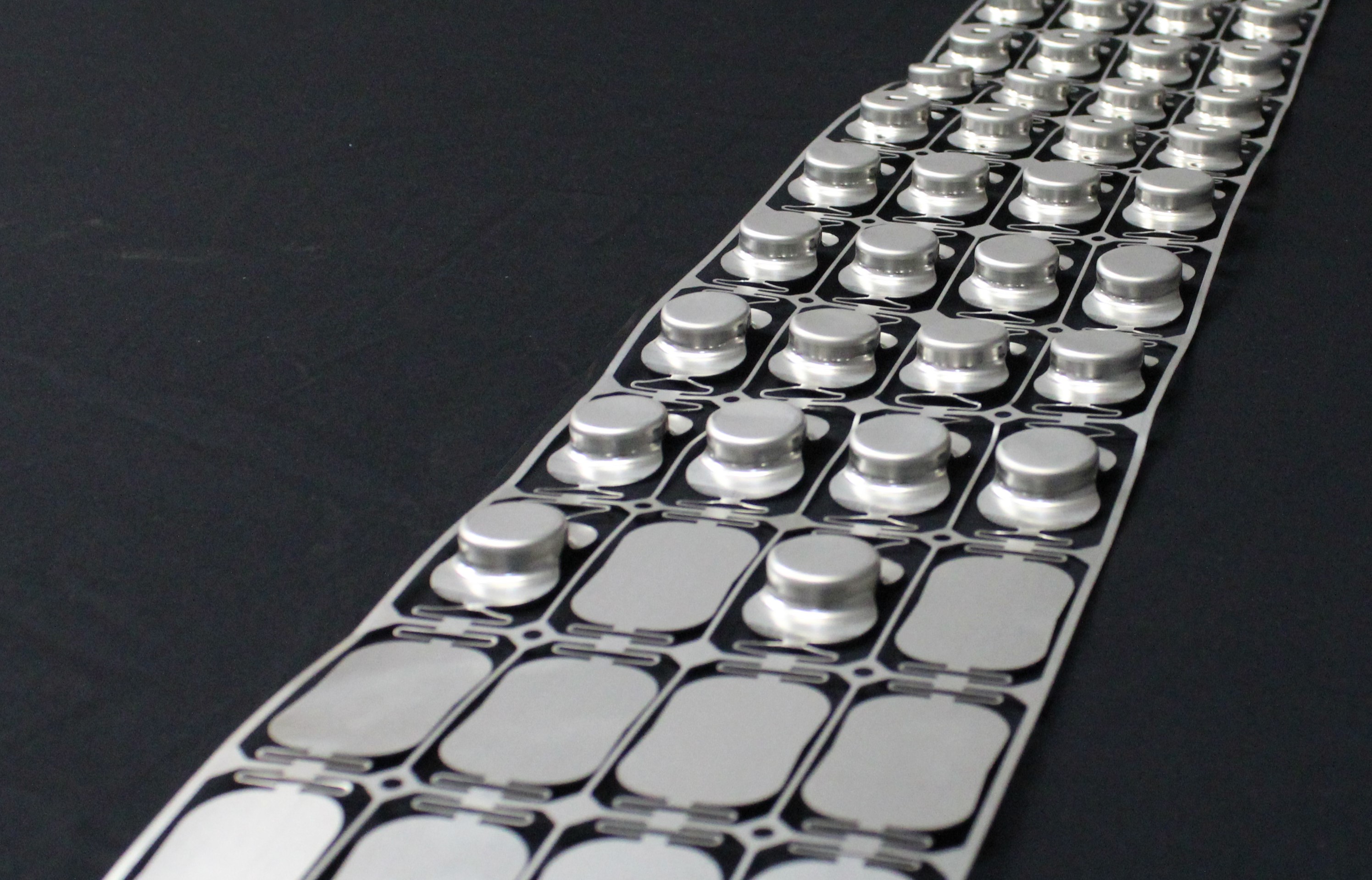

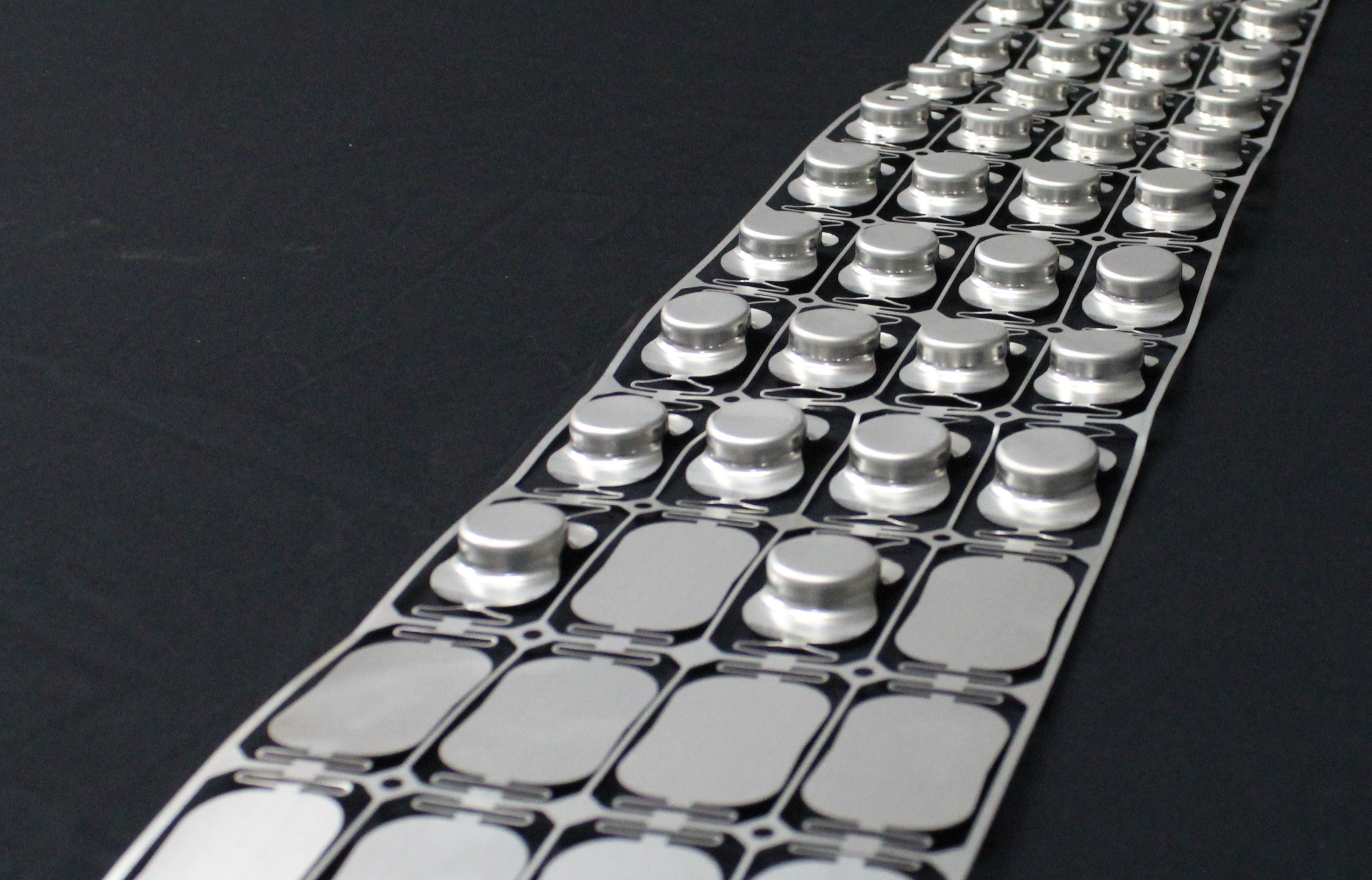

High Volume Progressive Die for Container Industry

Our customer was faced with increased demand and a desire to lower their production costs. They decided to add a punch press in their facility to run these parts in-house. WMPI helped with some consultation in selecting the proper metal stamping equipment and also worked with them to understand their overall goals with this project.

Our full-service tool room designed and built a pair of 4-out progressive metal stamping tools. These high-volume dies are designed to run 30,000,000 parts per year. This is an 18-station, 4-out progressive tool that will run at 150 strokes per minute in our 100-ton Minster press. Each time the die closes, it will be kicking out 4 finished parts. That’s 600 parts every minute, or 36,000 parts an hour.

These class-A dies are equipped with replaceable cutting and forming inserts that will allow for regular maintenance and many years of service. We’re running carbide inserts that should get us around 3-5 times more run time over tool steels before maintenance is needed. There are stripper plate sensors to detect slug pulling, a misfeed detector at the end of the tool, and eight sensors that take an actual measurement reading on two features within the part. If these features do not meet the program tolerances, the press will come to a stop. This helps keep nonconforming parts from slipping through into finished product.

We have also set them up with replacement wear items and will be available to help with tooling maintenance & repairs. The goal being to keep them up and running for years to come.

Click here to see this die running parts

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description | High Volume Progressive Die for Container Industry |

| Capabilities Applied/Processes | Tooling design & build. Progressive metal stamping |

| Equipment Used to Manufacture Part | 4-out progressive metal stamping die |

| Overall Part Dimensions | Die size: 15.5 x 21.0 x 54.0” Part size: .38 x 1.25 x 2.00” |

| Industry for Use | Container, storage industry |

| Volume | 30,000,000 parts/yr |