Company News, Press Releases, and Events

Wisconsin Metal Parts is the Waukesha County Business Alliance’s Medium Business of 2023!

We are overjoyed to announce that Wisconsin Metal Parts has been honored with the Waukesha County Business Alliance Medium Business of the Year Award for 2023!

Learn More

WMPI Wins the 2022 Wisconsin Manufacturer of the Year Award

We are thrilled to share that Wisconsin Metal Parts has been awarded the Single Source Supplier Award from Wisconsin Manufacturer of the Year Awards Association.

Learn More

.jpg)

Pewaukee Insight Program

Over the past year, Wisconsin Metal Parts has been working with the students from Pewaukee High School in the Pewaukee Insight program! This program is an education capstone designed to give students hands-on, real-world experiences in a professional setting. Wisconsin Metal Parts assisted in mentoring the students interested in business and marketing as a future career.

Learn More

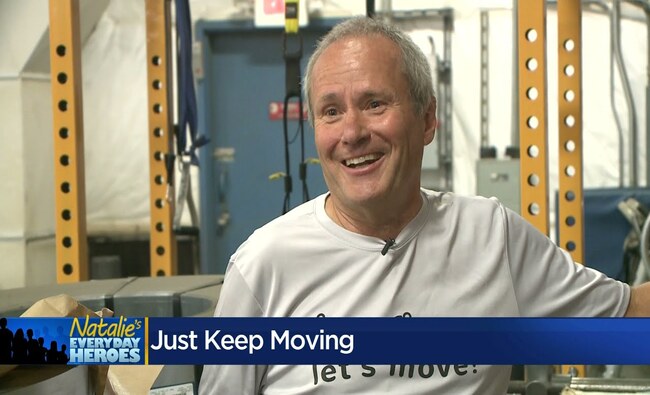

WMPI MS Program Partnership on CBS 58

The MS Just Keep Moving initiative supported by Wisconsin Metal Parts owner Dan Erschen was featured recently on the news for their work with the physical therapy program at Bryant and Stratton College. Students from the school come on-site to help those with MS who come to work out. Most of them are studying physical therapy and gain valuable hands-on experience while helping out here.

Learn More

WMPI Receives General Dynamics Supplier of the Year Award!

Wisconsin Metal Parts is honored to receive the 2020 General Dynamics Ordnance and Tactical Systems Supplier of the Year Award! Our team made this possible by serving General Dynamics for the past 3 years with Purpose, Pride, and Passion. We will use the excitement of this award to continue to invest in our people and technology.

Learn More

First Annual Fundraiser for the Milwaukee Homeless Veterans Initiative a Success!

Wisconsin Metal Parts recently celebrated its first annual brat fry fundraiser for the Milwaukee Homeless Veterans Initiative on Saturday, June 26th at Nettie’s Irish Pub.MHVI was suggested by a Wisconsin Metal Parts employee who has many family members who have served in the military, so they felt a personal connection with the cause.

Learn More

Wisconsin Metal Parts added a new machine to our CNC Department!

Wisconsin Metal Parts, Inc. (WMPI) continues to invest in new technologies and has added state-of-the-art equipment for the production of precision metal components. The new machinery enhances the company’s capabilities as a one-stop metal production shop.

Learn More

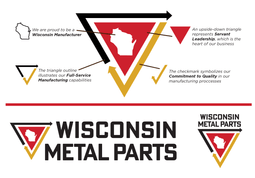

Wisconsin Metal Parts is Rebranding!

After 10 years with the new name Wisconsin Metal Parts, we have decided to try out a new look! We now have a logo for our company that highlights the history and structure of our company. Check it out:

Learn More

The Manufacturing Executive Podcast

Check out our president Dan Erschen featured on The Manufacturing Executive podcast! Joe Sullivan (host) and Dan talk about Servant Leadership in Manufacturing, some personal struggles and much more!.

Learn More

Wisconsin Metal Parts Launches 3 New Products

Over the last few months, Wisconsin Metal Parts Inc has been working on a handful of new products to share with other manufacturers. The S-Blade, Mini-Hopper and BIG FunL began as process improvements that were just too good to keep to ourselves! These products are designed to help manufacturers reduce risk, cycle time and save them money. Learn More

WMPI has been deemed an essential business and remains open during the COVID-19 Pandemic

With the Corona virus pandemic so prevalent in the news lately we have been hearing growing concerns from our customer base over production interruptions from both their overseas and domestic suppliers. Wisconsin Metal Part has already put plans into action to keep our workforce as safe as possible during these challenging times so we can continue to supply our customer base Learn More

Click here for your free Design2Part Registration 2020

Please visit Wisconsin Metal Parts at the Design2Part show in Grapevine, TX on February 26 & 27, 2020. Booth #301. Click on the link above to register your free admission invite.Learn More...

Top Workplace of 2020

Wisconsin Metal Parts was one of 150 companies in the Milwaukee area recognized by the Milwaukee Journal Sentinel as a 2019 Top Workplace! Top Workplaces are determined based solely on employee feedback and gathered by and administrated by an independent survey company . Companies are measured on qualities such as company leadership, career opportunities, workplace flexibility, compensation, benefits and the impact company policies have on innovation and morale. We realize our people are what make us successful, and we appreciate them, treat them with respect, make their job fun and reward them for their performance. Our high employee retention speaks volumes. To learn more about employment opportunities at WMPI, click here.

Click here for your free Design2Part Registration 2019

Please visit Wisconsin Metal Parts at the Design2Part show in Schaumberg, IL on May 8th & 9th. Booth #140. Click on the link above to register your free admission invite. Learn More...

Wisconsin Metal Parts Participates in Manufacturing Month 2018

Waukesha, WI – STEM Academy Schools2Skills Tour, MADE Career Expo, Workforce Development Job Fair, and More As a leading provider of metal fabrication, stamping, CNC machining and complete tool & die services, Wisconsin Metal Parts, Inc. (WMPI) serves the manufacturing industry not only in the Midwest, but on a national & global scale as well. click here.

Wisconsin Metal Parts, Inc. Launches New Website

Waukesha, WI – Wisconsin Metal Parts, Inc. (WMPI) has launched a new mobile-friendly website site which better showcases their services along with why WMPI is a great place to work. click here.

Top Workplace of 2018

Wisconsin Metal Parts was one of 150 companies in the Milwaukee area recognized by the Milwaukee Journal Sentinel as a 2018 Top Workplace! Top Workplaces are determined based solely on employee feedback and gathered by and administrated by an independent survey company . Companies are measured on qualities such as company leadership, career opportunities, workplace flexibility, compensation, benefits and the impact company policies have on innovation and morale. We realize our people are what make us successful, and we appreciate them, treat them with respect, make their job fun and reward them for their performance. Our high employee retention speaks volumes. To learn more about employment opportunities at WMPI, click here.

Click here for your free Design2Part Registration 2018

Please visit Wisconsin Metal Parts at the Design2Part show in Schaumberg, IL on May 9th & 10th. Booth #140. Click on the link above to register your free admission invite. Learn More...

WMPI MS exercise facility on Sunday Morning Spotlight

WMPI's in-house exercise facility, created by President Dan Erschen, was featured on CBS Sunday Morning. It caters specifically to local community members battling multiple sclerosis. Learn more...

Wisconsin Metal Parts, Inc. Recognized for Growth

WMPI was recognized by the Milwaukee Business Journal as one of the Milwaukee-areas fastest growing firms. The 23 award winners were chosen based on the highest percentages of growth between 2014 and 2016. Learn more...

A Local Perspective on Women and Millennials in Manufacturing

As manufacturing evolves, Wisconsin Metal Parts, Inc. (WMPI) in Waukesha is tapping into at least two groups in the work force whose manufacturing roles are expanding: millennials and women.

Skills gaps and science, technology, engineering and mathematics (STEM) education are still hot topics in manufacturing. At WMPI, both the younger and female employees – two groups who have been traditionally under-represented in manufacturing – do a wide variety of jobs and come from diverse backgrounds. They also seem to share several motivators: they enjoy learning, they embrace technology, and they value making other people’s jobs easier. WMPI gives them opportunities for all of those things. Learn more...

Click here for your free Design2Part Registration 2017

Please visit Wisconsin Metal Parts at the Design2Part show in Schaumberg, IL on May 10th & 11th. Booth #140. Click on the link above to register your free admission invite. Learn more...

Wisconsin Metal Parts Continues Investing in Fabrication Equipment

WMPI continues to invest in new technologies and has added state-of-the-art equipment for the production of precision metal components. Learn more...

WMPI Adds New High-Speed Milling Equipment

WMPI has added a new high-speed milling machine to its production CNC machining area, which will be used to process some of their higher volume metal production parts. Learn more...

Click here for your free Design2Part ETicket 2016

Please visit Wisconsin Metal Parts at the Design2Part show in Schaumberg, IL on May 11th & 12th. Booth #138. Click on the link above to download your free admission invite. Learn more...

WMPI Combines its Fabrication Operations into a New Single Location

WMPI moved its metal fabrication shop and fabrication equipment to a 27,000-sq.-ft. manufacturing facility, giving additional manufacturing space and improved logistics and material handling capabilities. Learn more...

WMPI Adds to its Fabricating Capacity

WMPI recently added to its solid state laser metal cutting capabilities. They now have open capacity to process an additional two to three semi-loads of material per week (150 to 180 hours of beam time). Learn more...

FabTech Show - Express Registration

Please visit Wisconsin Metal Parts at the FABTECH show at McCormick Place in Chicago, IL on Nov. 9-12, 2015. South Hall Booth #S2008. Click on the link above to register. Learn more...

Setting the Pace for Success

How our employees set the pace for success was recognized in the July 2015 issue of The FABRICATOR®. Learn more...

WI Robotics

Wisconsin Metal Parts sponsored the May 9, 2015 BotsIQ Wisconsin competition at WCTC where 87 students from nine different schools competed to see who could design and build the best robot. The construction of their bot also exposes them to many different advanced manufacturing careers. This program is helping to train tomorrow's workforce. Learn more...

Design2Part ETicket 2015

Please visit Wisconsin Metal Parts at the Design2Part show in Schaumberg, IL on May 6th & 7th. Booth #138. Click on the link above to download your free admission invite.

Wimoty Nomination

Wisconsin Metal Parts, Inc. was nominated for the 2014 Wisconsin Manufacturer of the Year Award. This award recognizes manufacturers for their paramount economic contributions to the state of Wisconsin. Learn more...

FFJournal

Having asked our customers where they needed our support in the future, we invested in new technologies that help reduce their cost per part, improve quality and speed up turnaround times. In 2014, we purchased two new 5,000-watt fiber lasers, a 300-ton electric press brake, a third building and added off-shift capacity. We expanded our manufacturing space to over 75,000 sq. ft. while running 3 shifts. Our growth and success was well documented in the December 2014 issue of FFJournal. Learn more...