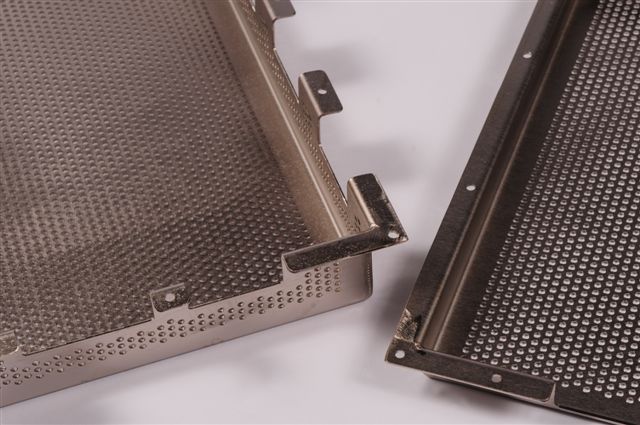

Defense Industry Chassis Cover

This part was created using our CNC punching machine. The corners were welded and ground smooth and then this part was sent out for plating per our customer's specifications.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description | Defense Industry Chassis Cover | ||

| Capabilities Applied/Processes |

|

||

| Equipment Used to Manufacture Part | Trumpf 1000 CNC Punch, Trumpf 5085 CNC Brake, Lincoln welder | ||

| Overall Part Dimensions | Length: 16.00” Width: 10.00” Thickness: 2.5” |

||

| Tightest Tolerances | ±.015” | ||

| Material Used | CRS | ||

| Max Material Finish | 63Ra | ||

| In Process Testing/Inspection Performed | First Article, Functional testing | ||

| Estimated Part Weight | 2 lbs. | ||

| Industry for Use | Electronic Equipment | ||

| Volume | 175 | ||

| Delivery Location | East Coast, USA | ||

| Standards Met | Customer supplied print, 2D CAD Drawing, MIL specifications ASME Y14.5M-1994 Material certifications Geometric Tolerancing Plating Specs |

||

| Product Name | Perforated Cover |