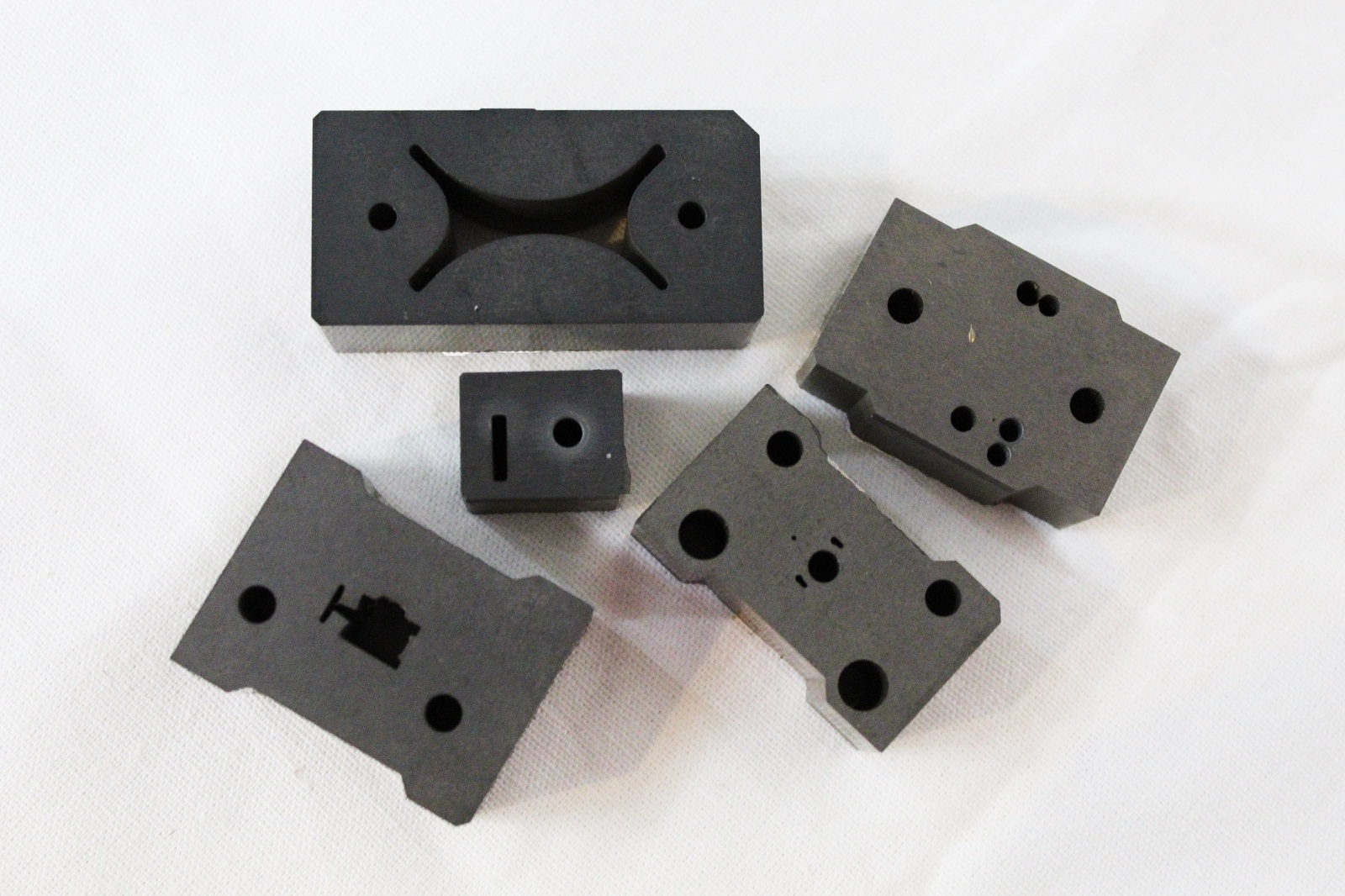

Quick turnaround on Wire EDM Die Parts

We support industries that require very tight tolerance contoured replacement carbide punch & die inserts. We have held tolerances down to +/-.00005” and in these cases, if the inserts are installed in the die and the punches enter without clicking the inserts are considered good. Our customers are typically running millions of parts before inserts are replaced. We have a process that protects the carbide during WEDM so the integrity of the carbide is maintained for longevity of cut edges. We also use a premium brand of carbide that is designed specifically for this purpose. Depending on what material we have in stock, lead times can be as short as a few days. Typically, our AGIE Wire EDM machines can create finishes as fine as 4 Ra” in carbide and 8 Ra” in Tool Steels. Our machines run in a climate-controlled area creating ideal conditions for very tight tolerance work.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description | Often within 1 week from PO |

| Capabilities Applied/Processes | Wire EDM |

| Equipment Used to Manufacture Part | AGIE VP3 |

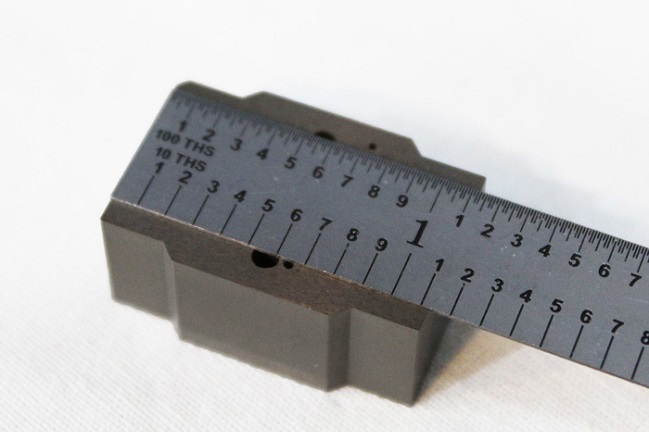

| Overall Part Dimensions | Varies by part |

| Tightest Tolerances | +/-.00005" |

| Material Used | Carbide |

| Max Material Finish | 4 Ra" |

| In Process Testing/Inspection Performed | Sizes checked with Deltronic pins. If the inserts are installed in the die and the punches enter without clicking, sizes are considered good. |

| Estimated Part Weight | Varies by part |

| Industry for Use | Computer Hardware |

| Volume | Tooling replacement components, typically 1-10 piecespot buys. |

| Delivery Location | Various locations throughout USA |

| Standards Met | Customer specific standards |