Industries - Automotive

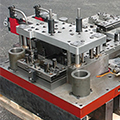

Working with automotive suppliers around the world, WMPI produces parts that require multiple manufacturing processes, from tool and die making to metal fabrication and stamping. We understand the pressure faced by automotive suppliers to reduce costs yet maintain strict quality and reliability standards. Our engineering expertise, continuous process improvement and numerous manufacturing processes help us meet these low-cost initiatives while providing the highest quality tool and die products, metal parts and assemblies.

WMPI has served automotive suppliers for many years. We offer innovative prototyping and reverse engineering services, and we produce precision parts and complex assemblies for automotive components in areas such as:

- Chassis

- Engine

- Transmission

- Interior Trim

For more information about our manufacturing capabilities and how we can help with your project, please contact us today.