Tool and Die Designers and Builders

What can we do for you?

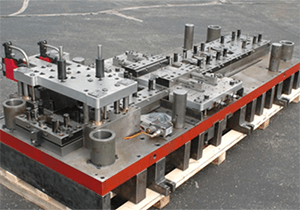

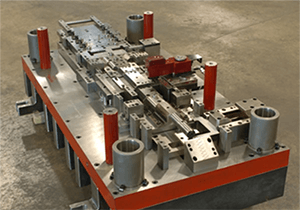

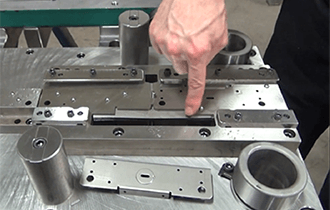

Wisconsin Metal Parts, Inc. designs and builds all tooling in-house. Our design and engineering team uses the most up-to-date forming and stamping simulation software to help you validate the final design before building the die. We can assist material selection and identify potential problem areas to help you best design your metal part or assembly for manufacturability. Our full-service tool room is staffed by expert toolmakers with two shifts to meet your tight deadlines.

WMPI will keep you informed regularly on your tooling progress. Our prototype options include soft /low-volume tooling, WEDM, CNC machining and laser cutting available in-house. With CNC Machining, Fabrication, CNC Grinding, Wire EDM and secondary support presses, we can be a single source for your assembly and sub-assembly needs. Get us involved early and we will help you spend your money wisely.

Our Technology

Wisconsin Metal Parts invests in technology such as new Agie Wire EDM, CNC surface and form grinding and CNC machines that improve quality and speed turnaround times. We offer full feed lines on all presses (30 to 200 tons) so your tooling is debugged and running at production speed before we ship it. We are experts at building “Class A,” progressive, single-hit, form, draw, insertion, in-die tapping, fine blank, compound dies and more. We also design and build inspection gages, fixtures and components as well as perform die repairs and maintenance. We can assist you with die sensor selection to protect your tools.

Die Repair and Maintenance

Keep your dies running as long as possible with a preventative maintenance plan. This will extend the life of your die and keep high-quality, conforming parts coming off of your tool. Do you only need a few repairs? Reach out to us and we can talk about the best options for the health and upkeep of your tooling.

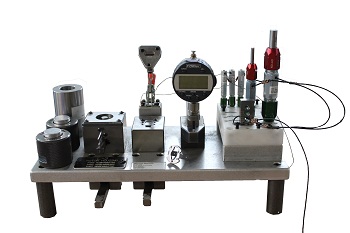

Inspection Gages

Functionalgaging can help reduce in-process quality control time and costs, reduce bottlenecks at your CMM and improve your overall inspection process. Are you producing consistent high quant ties of parts? It might be time to consider getting inspection gages to help streamline your quality process.

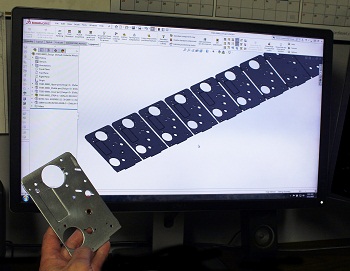

Prototyping and Reverse Engineering

Have the part but not the drawings? Need some pre-production prototypes? Have damaged components on a tool that needs to be replaced? Our team has the tools to get you running production as soon as you can, using a combination of our manufacturing departments.

CNC Surface and Form Grinding

If your parts need special surface finishes or have tight corners and contours, we can offer repetitive production surface grinding with tolerances to ".0001" and finishes as fine as SRa.

What is Progressive Stamping Die?

Frequently Asked Questions about Tool and Die Making

Our main competency is progressive dies, but we build other dies such as draw, deep draw, single hit, compound, fine blank, transfer and a variety of other tools.

Yes, we have a full-service tool room that includes design and build.

Tooling is custom to the part that it is producing, so that will be completely driven by your part print. We have built tooling that makes parts so small that several could fit on a dime. We have also built tooling that makes larger parts, up to .25” thick. We are only limited by tonnage, which is currently 200 tons.

Depending on the project, lead times could be a few weeks to several months, depending on the size and complexity of the tooling.

Yes, we have presses with full feed lines. Our team will debug and get tooling running acceptable parts at production rate before shipping your tooling.

Our tool team leaders send out weekly progress reports showing planned and actual progress. If we are behind, we will communicate that and share our plan to get caught up.

We do make prototypes here. Some might be parts that you just want to hold in your hand and can be produced by any means economical. Or they could be pre-production proto types that need to be produced by actual tooling to be used for testing. We can handle a wide variety of prototyping requirements and inspection options.

Typically, a PPAP is performed by the company that is running the production. If we are building the tool and running it here then we would take care of the PPAP, if that is required. If you (or someone else) are planning to run the production, we will normally provide First Article parts and inspection data from our runoff before shipping the tool. This process is most often driven by individual customer requirements.

Photo Gallery

Photo Gallery Capabilities

Capabilities Videos

Videos Quality Management

Quality Management