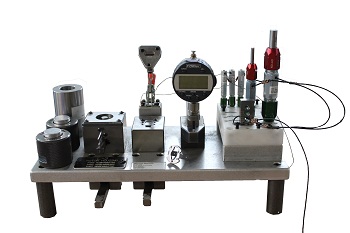

Inspection Gages CMM Fixtures

Calibrated and Certified

Our gage team at Wisconsin Metal Parts will work very closely with your engineers to ensure that your gaging checks and controls features critical to your part print and the parts intended function. We design, build and calibrate all gages in our full-service tool room. All designs are completed using Solidworks.

Design & Construction of Your Gages & Fixtures will be based on:

- Defining critical features that need to be checked

- Applying geometric tolerances & datums

- Simulating how the part is being used & held in assembly

- Providing instructions & procedures for using the gage or fixture

- Labeling of components

- Certifying critical features of the gage

- Applying cost-effective solutions to designing, building & using the gage

- Meeting short lead times

- Providing reliable inspection results that you can trust

What can we do for you?

Send us your part print with tolerances and a 3-D part model. From there we can start the conversation about the goals of this gage. Tell us what you need and we will find a way to get you there.

With our compliment of Metal Stamping, Fabrication, CNC Machining, CNC Grinding, Wire EDM, we can be a single source for your tooling, assemblies and metal parts needs. Get us involved early and we will help you spend your money wisely.

Frequently Asked Questions about Inspection Gages

We design and build gages and fixtures in our toolroom.

We build gages that can check parts with go/no-go features, attribute checks, assembly simulations and also develop fixtures for holing parts in your CMM. Our quality department can calibrate and certify your gage before you start using it.

Depending on the project, lead times could be a few weeks or more, depending on the size and complexity of the tooling.

Yes, we have a full design team: all we would need is your part print and model to get started!

We build gages that can check parts with go/no-go features, attribute checks, assembly simulations and also develop fixtures for holing parts in your CMM. Our quality department can calibrate and certify your gage before you start using it.

Inspection gages help reduce in-process quality control costs while still maintaining quality requirements. It allows the trained operators to perform in-process inspection at the machine or press. Gages can also help reduce bottle necks at your CMM Equipment, and bring consistency into your inspection plan by ensuring that everyone is checking consistently for the same potential issues.

Photo Gallery

Photo Gallery Capabilities

Capabilities Videos

Videos Quality Management

Quality Management