Outsourcing Assembly

Moving Assembly Manufacturing for the First Time

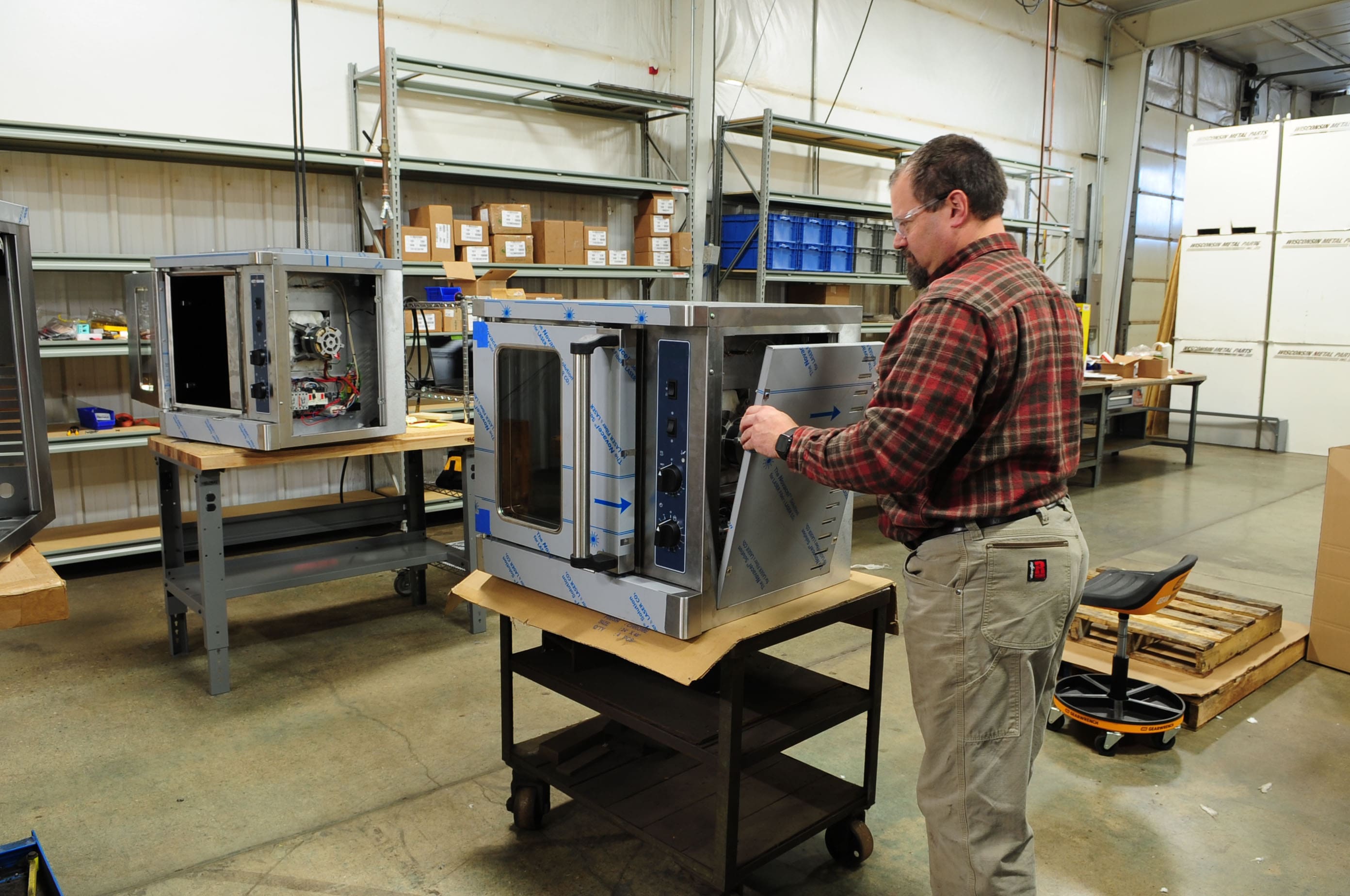

A local OEM that produces foodservice equipment was trying to gain floorspace in their manufacturing plant to develop more complex products. They needed to move and outsource their manufacturing cell to save space and find a more effective system for manufacturing their products. Our team went to their plant, took detailed notes on their manufacturing process in order to develop an efficient method to produce their product. We were able to redo pricing, and after a few pilot builds we now produce their convection ovens for them under blanket orders. We became UL certified as a satellite manufacturer and continue to meet and exceed their quality requirements. They now have the space they need to work on new products to better serve their customers.

Need assistance getting your products to market quickly, efficiently and as cost-effectively as possible? Contact Us

Request a Quote