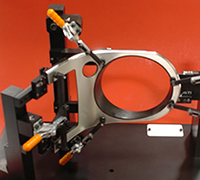

CMM Trim Fixture

Wisconsin Metal parts designed this fixture to hold a molded plastic interior trim part with a formed aluminum shell on it. The fixture allowed our customer to quickly and repetitively check production parts on its CMM while also performing some attribute checks.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description |

|

||

| Capabilities Applied/Processes |

|

||

| Equipment Used to Manufacture Part | Grinding, WEDM, Jig grinding, CNC machining, Anodize, Oxide | ||

| Overall Part Dimensions | Length: 18” Width: 18” Heighst: 12” |

||

| Tightest Tolerances | ±.0005” | ||

| Material Used | Aluminum, tool steel | ||

| Max Material Finish | 63Ra | ||

| In Process Testing/Inspection Performed | CMM inspection, 3rd party certification | ||

| Lead Time | 5 weeks | ||

| Industry for Use | Automotive | ||

| Volume | 375 | ||

| Delivery Location | Wisconsin | ||

| Standards Met | Customer supplied print, 2D CAD Drawing, Customer gage requirements | ||

| Product Name |

CMM Trim Fixture |