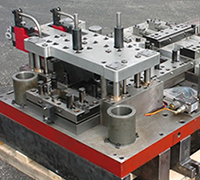

Automatic Hardware Insertion Tooling

One of our Tier 2 automotive supply customers came to us with a part they wanted to run in their stamping department. For this high-volume project to be profitable for them, they felt they needed to insert hardware into the progressive stamping die to produce a complete part, reducing their labor requirement.

Our design team worked with their engineering staff to model a concept and find the insertion unit that would work best for their application. In 12 weeks, WMPI built this tool and had it debugged, set up on our full feed line, and running at the targeted run rate in our 200-ton press. In the end, this insertion reduced the part cost by $.42 and we delivered tooling to another happy customer.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description |

|

||

| Capabilities Applied/Processes |

|

||

| Overall Part Dimensions | Length: 24” Width: 60” |

||

| Tightest Tolerances | ±.0005” | ||

| Material Used | A-2, D-2, M-2, CPM, 4140, Carbon Steel | ||

| Max Material Finish | 125Ra | ||

| In Process Testing/Inspection Performed | First Article, CMM, Inspection Gage, 500 piece runoff | ||

| Lead Time | 14 Weeks | ||

| Industry for Use | Automotive | ||

| Volume | Tooling designed to run 1,000,000 hits | ||

| Delivery Location | Western, USA | ||

| Standards Met | Customer supplied print, 2D CAD Drawing, customer die standards, First Article approval, Runoff | ||

| Product Name |

Progressive die with in-die insertion unit |