Example Projects

At Wisconsin Metal Parts, we take great pride in the quality of our work. From stainless steel fabrication projects to progressive die stamping and CNC machining, we adapt our services to meet your unique requirements. To get a feel for the kind of work we do, please explore the example projects below.

Contract Manufacturing & Assembly

Stainless Steel Biodigester

A manufacturer in the food service industry had a single supplier that was no longer able to keep up..

Learn More

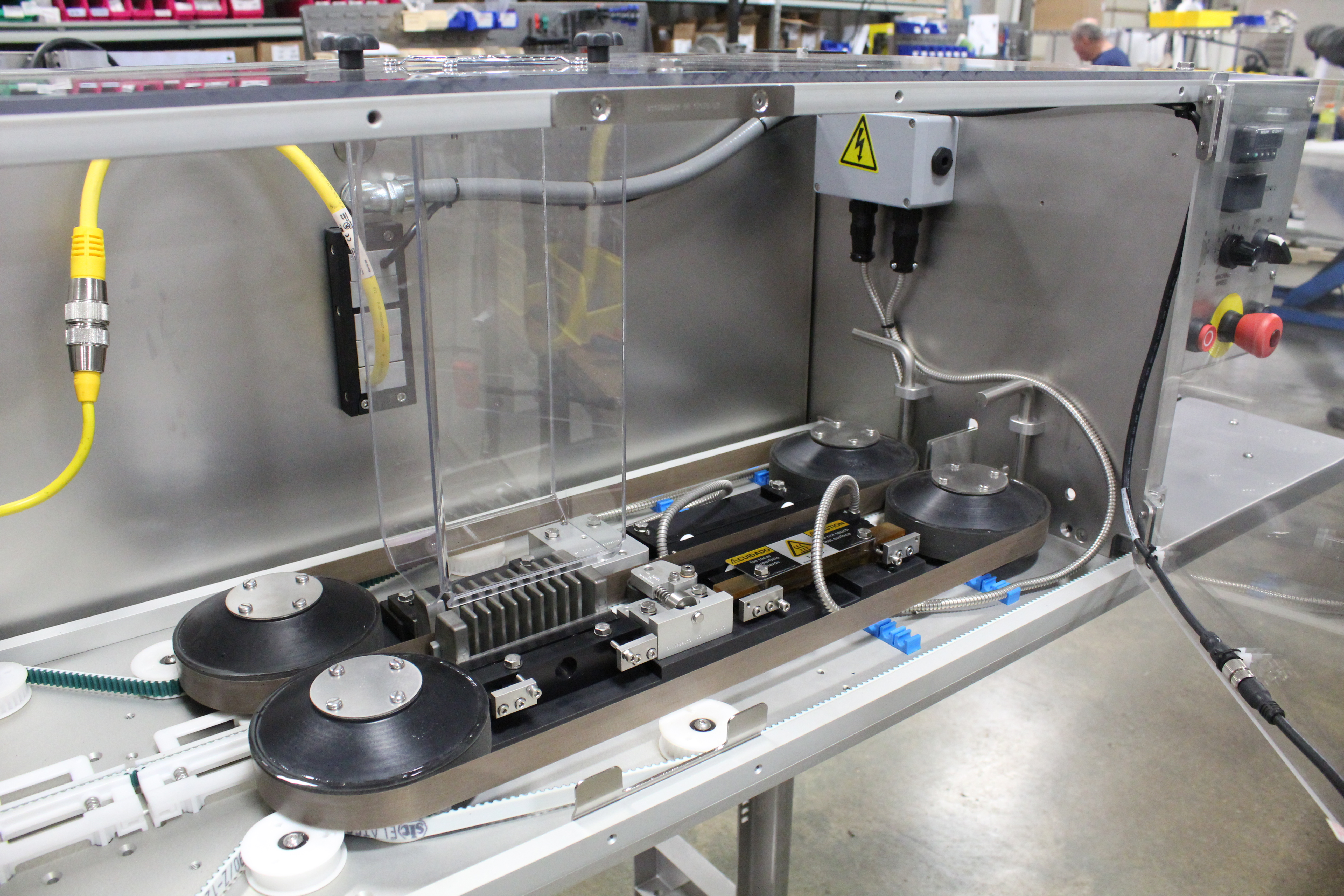

Mounting Bracket Sub-Assembly

WMPI has supported a customer in the fluid metering industry with services ranging from prototypes..

Learn More

Instant Production Capacity

A manufacturer finds fast relief from the pressure of year-end shipping goals..

Learn More

Weldments that Require Machining

An industrial equipment manufacturer wanted to relocate some of its current production from another vendor..

Learn More

Foodservice Equipment Takeover

How one company outsourced production so they could focus on other projects..

Learn More

Heat Transfer Industry Production Cells

Our customer got us involved early in this project and we helped develop this Heat Transfer ..

Learn More

Construction Industry Threaded Holder

This stainless steel threaded assembly is manufactured complete using our CNC lathes and milling machines.

Learn More

Printing Industry Cabinet

This steel cabinet is fabricated on our laser and CNC punching machine..

Learn More

Machine Equipment Thermostat

These stainless steel thermostat assembly components are manufactured using our deep draw..

Learn More

Sheet Metal Fabrication

Electronics Enclosure

This production part was previously made in China and suffered from quality issues..

Learn More

Copper Busbars

A customer in the power storage industry consulted WMPI when they needed a package of thin-gage copper busbars..

Learn More

Electronic Storage Cabinet

A customer planned to manufacture an electronic storage cabinet to house hardware..

Learn More

Aluminum Enclosure Panel

An OEM came to us for fabrication of an aluminum enclosure panel that would be part of a medical diagnostic device.

Learn More

Steel Front Loader Assembly

A manufacturer of industrial equipment came to Wisconsin Metal Parts, Inc. (WMPI) for production of a front loader..

Learn More

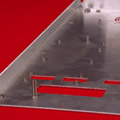

Stainless Steel Clamping Fixtures

A client from the heat transfer industry came to us for a clamping fixture..

Learn More

Fiber Laser Cutting

Copper Busbars

A customer in the power storage industry consulted WMPI when they needed a package of thin-gage copper busbars..

Learn More

Rush Fabrication Work.

A WMPI production customer needed a lot of next-day/ same-day spot purchase support to complete..

Learn More

Reshoring to Improve Quality

Our customer came to us experiencing quality issues from their overseas supplier.

Learn More

1010 Steel Computer Chassis

Using a combination of our laser, punching machine and CNC brake we have created prototype samples..

Learn MoreWelding

Instant Production Capacity

A manufacturer finds fast relief from the pressure of year-end shipping goals.

Learn More

Weldments that Require Machining

An industrial equipment manufacturer wanted to relocate some of its current production from another vendor.

Learn More

Printing Industry Cabinet

This steel cabinet is fabricated on our laser and CNC punching machine..

Learn More

Steel Front Loader Assembly

A manufacturer of industrial equipment came to Wisconsin Metal Parts, Inc. for production of a front loader assembly..

Learn MorePrototyping & Reverse Engineering

Motor Housing Prototype

Our customer came to us with a need for short lead-time prototypes..

Learn More

Stainless Steel Medical Cabinet Prototype

This stainless steel cabinet was designed and prototyped for the medical industry..

Learn More

Electrical Contact Insert Prototype

Pre-production prototypes were needed for this brass contact..

Learn More

Reverse Drawn Cup Prototype

Pre-production prototypes were needed to prove out process on this steel cup..

Learn More

Rolled Up Stamping Prototype

Here is a variety of pre-production prototypes that were rolled up and/or staked in the tool..

Learn More

Aerospace Gear Pump Cover Prototype

This aluminum housing cover is used in the aerospace industry..

Learn MoreCNC Machining

Shell Casing Machining

Our customer needed quick turnaround for CNC machining on shell casings..

Learn More

Stainless Steel Casting Marine Application

Working with our customer, we marked up a drawing with cost savings ideas that allowed us to machine a part..

Learn More

Complex Aluminum Casting Machining

Our die cast customer came to us needing support to machine their tighter tolerance, more complex work..

Learn More

Metal Stamping and CNC Machining

WMPI was presented with a stamped part that needed secondary machining on an O-ring groove track..

Learn More

Zinc Die Cast Motor Housing

Weighing less than 1 lb., this zinc motor housing casting was designed to be used in an electric motor assembly and sent to us..

Learn More

Aluminum Turning Rack Castings

As a direct result of our expertise in CNC machining of castings, a client in the storage and shelving industry..

Learn More

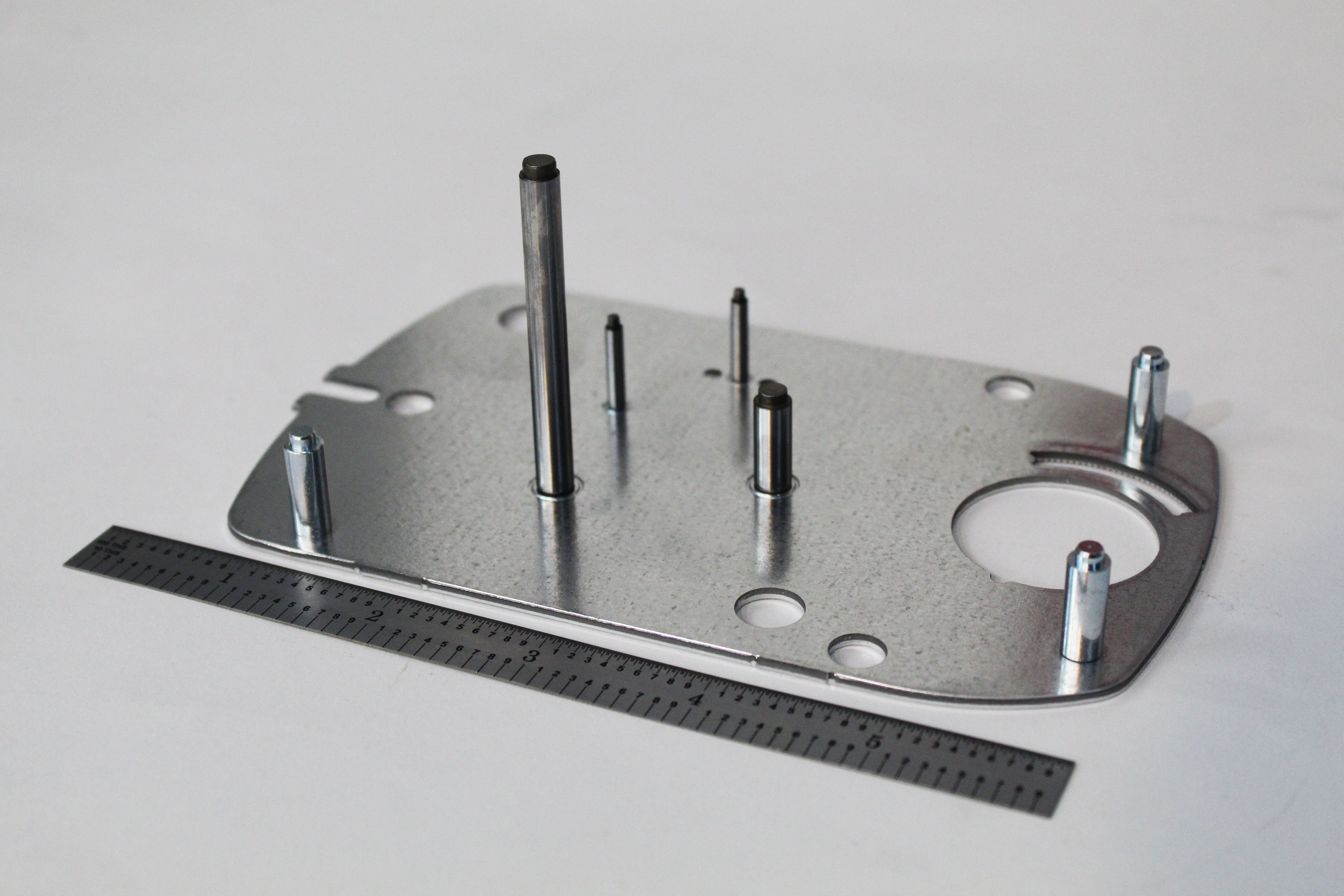

Steel Detent Plates

A client from the security industry approached Wisconsin Metal Parts, Inc. for the fabrication of a steel detent plate..

Learn More

Cast Steel Gear Housing

We built a hydraulic fixture in-house to allow for high precision machining in our horizontal OKK machining center.

Learn More

Stainless Steel Dispensing Nozzles

These stainless steel dispensing nozzles were machined complete on our Samsung SL25 lathe with live tooling.

Learn MoreStamping Takeovers

Industrial Safety Components

Our customer was struggling with another production stamping supplier regarding quality and delivery..

Learn More

Military Ordnance

This manufacturer originally consulted Wisconsin Metal Parts because its current stamping supplier..

Learn More

Industrial Brush Brackets

A manufacturer of industrial brush brackets was having difficulty keeping a skilled workforce to run parts..

Learn MoreCustom Metal Stamping

.jpg)

Clamp, Prototype to Production

This clamp project started off needing a few R&D test samples made with WMPI’s fiber laser and brake press..

Learn More

Mounting Bracket Sub-Assembly

WMPI has supported a customer in the fluid metering industry with services ranging from prototypes produced in..

Learn More

Brass Timing Wheels

A brass timing wheel was needed by a defense contractor and they turned to Wisconsin Metal Parts, Inc to handle this..

Learn More

Electrical Contact with In-Die Insertion

We built a progressive stamping die complete with in-die pin insertion to efficiently make these electrical contacts..

Learn MoreTool & Die

Arming, Timing & Fuze Delay Tooling

WMPI supports our production stamping with a full-service tool room that designs and builds..

Learn More

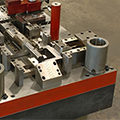

Progressive In-Die Tapping

This progressive stamping tool has an in-die tapping unit to add a threaded hole to the flange..

Learn More

Automatic Hardware Insertion Tooling

One of our Tier 2 automotive supply customers came to us with a part they wanted to run..

Learn More

Bracket Attribute Gage

This gage was designed to check attributes and limits on left- and right-hand parts as they were coming off the die.

Learn More

CMM Trim Fixture

Wisconsin Metal parts designed this fixture to hold a molded plastic interior trim part with a ..

Learn More

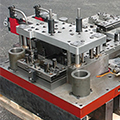

High Volume Progressive Die

Our customer was faced with increased demand and a desire to lower their production costs.

Learn MoreWire Electrical Discharge Machining (WEDM) Services

Shower Nozzles

These parts required us to design and build a progressive stamping die to cut/form stainless steel blanks that..

Learn More

Steel Detent Plates

A client from the security industry approached Wisconsin Metal Parts, Inc. for the fabrication of a steel detent plate..

Learn More

Precision Carbide Punches & Die Inserts

We support industries that require very tight tolerance contoured replacement carbide punch & die..

Learn MoreContinuous Improvements

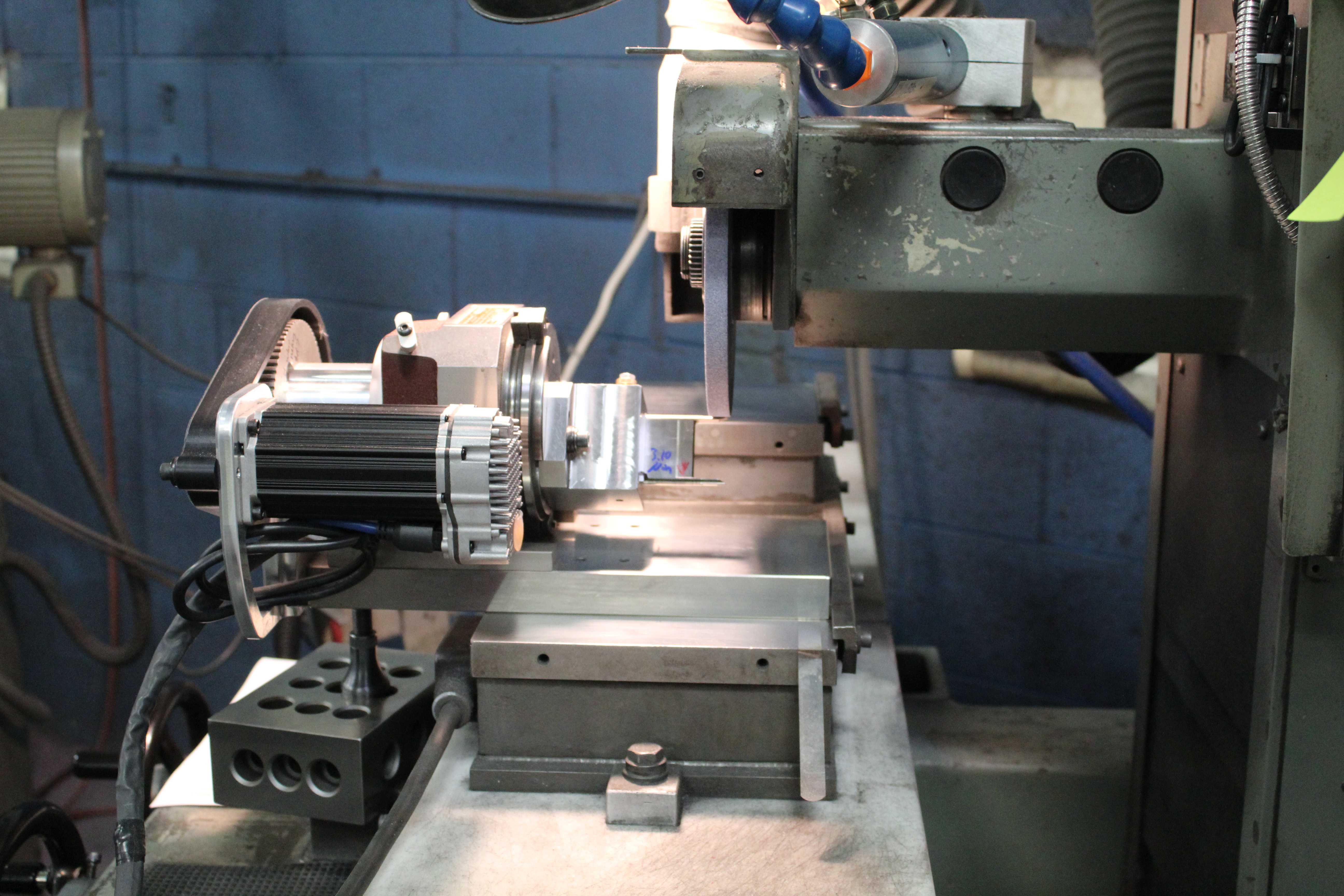

Automating Surface Grinder Accuracy

A part we make for a customer required different radiuses with extreme tolerances. The only way to produce this part was to use our surface grinders and a spin fixture...

Learn More

Important Links

Get in touch

- Fabrication:

- 404 Pilot Ct

- Waukesha WI 53188

- Stamping & Machining:

- N4W22450 Bluemound Rd

- Waukesha WI 53186

- Phone No.: (262) 524-9100

-

© 2024, All Rights Reserved

Wisconsin Metal Parts LLC

Privacy | Sitemap

Site: Marketing Metrics Corp