Efficient Outsourcing

Increased Production Capacity and Assembly Support

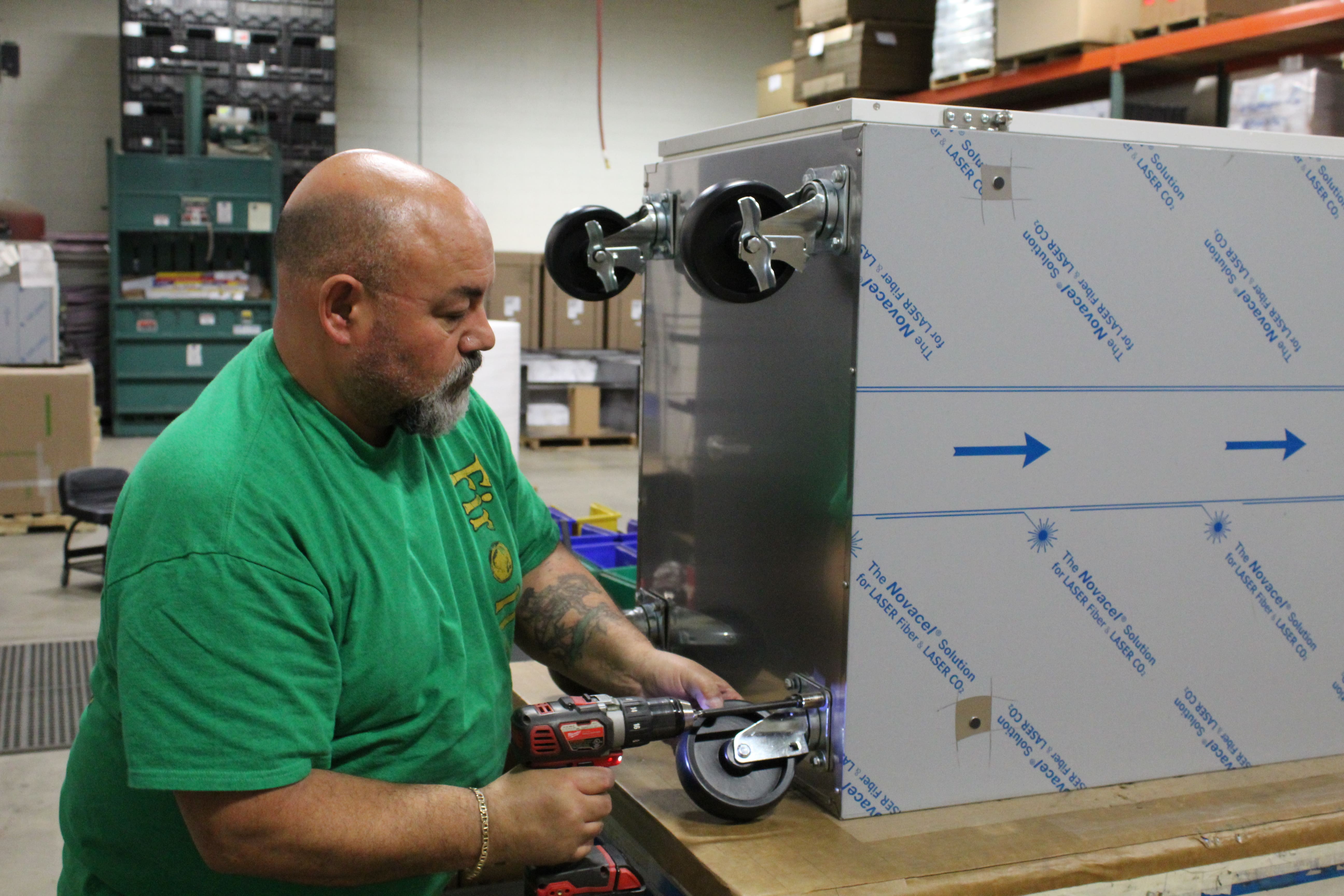

This foodservice manufacturing vendor was originally making these warming cabinets in house, but needed the space to develop new projects, could not keep up with their demand, and needed a more cost-effective process. Wisconsin Metal Parts was able to step in and take over production, and within three months we had a new cell up and running and were producing units at a more effective rate than before! We went through UL certification as a satellite manufacturer. We assemble the units and test for heat, perform hipot testing, put in owner’s manuals, and ship direct to their customers. Output has sat around 150 units a month, for 4 years with scarce quality issues! We were able to keep over 100 units in inventory at all times for them, something that they were unable to do when the project was in-house. Within a year of beginning this project we were able to provide and exceed their requirement of units for selling and safety stock in inventory.

Need assistance getting your products to market quickly, efficiently and as cost-effectively as possible? Contact Us

Request a Quote