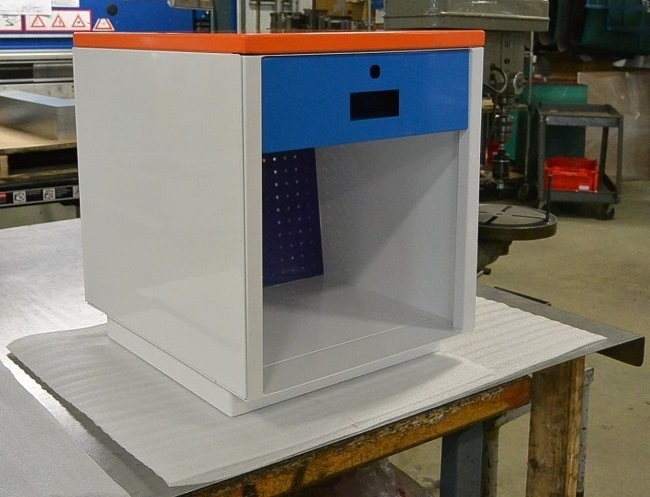

Electronic Storage Cabinet

A customer planned to manufacture an electronic storage cabinet to house hardware. They called on WMPI because we could offer manufacturing input and help them develop and build a group of prototypes before they’d proceed with eventual production. This project had an aggressive timeline to meet their end customers’ needs.

WMPI’s engineering team reviewed the project as a whole, asking questions and learning what was truly important on these units. From there, our team worked to provide the best manufacturing process suggestions. The customer incorporated WMPI’s cost-saving ideas into their design, and we successfully helped them reach their part cost goals.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description | Electronic Storage Cabinet for Holding Hardware | ||

| Capabilities Applied/Processes |

|

||

| Equipment Used to Manufacture Part | Fiber Laser, CNC Punching, Press Brake, Hardware Insertion, Spot Welding, Assembly | ||

| Overall Part Dimensions | 18 x 20 x 28” | ||

| Tightest Tolerances | ±.010" | ||

| Material Used | HRPO Sheet steel | ||

| Max Material Finish | |||

| In Process Testing/Inspection Performed | Fit & Function | ||

| Estimated Part Weight | 35 lbs. | ||

| Industry for Use | Electronics | ||

| Volume | 10-15 | ||

| Delivery Location | East Coast, USA | ||

| Standards Met | Customer supplied print, 2D CAD Drawing MIL specifications ASME Y14.5M-1994 MIL-C-5541 |

||

| Product Name | Electronic Storage Cabinet |