Custom Metal Stamping

What can we do for you?

Wisconsin Metal Parts, Inc. (WMPI) custom metal stamping service delivers the highest quality precision metal stampings from prototype to production-level quantities. Our proven thirty-year track record of outstanding craftsmanship and customer service guarantees you will receive exactly what you require for your assembly and pre-assembly needs, on time and at a competitive cost.

We run nearly 60 million stampings per year at a 98% on time delivery rate.

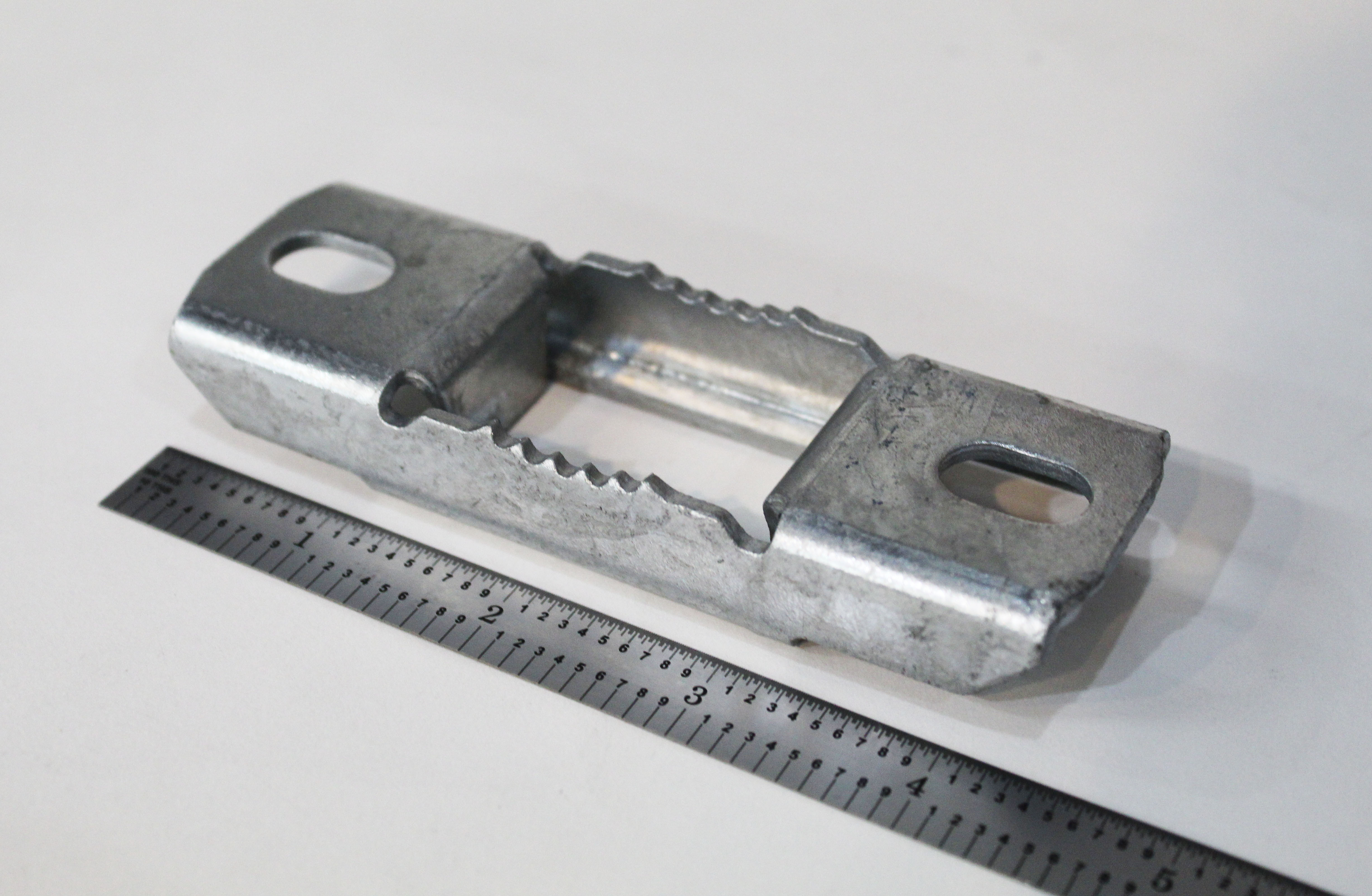

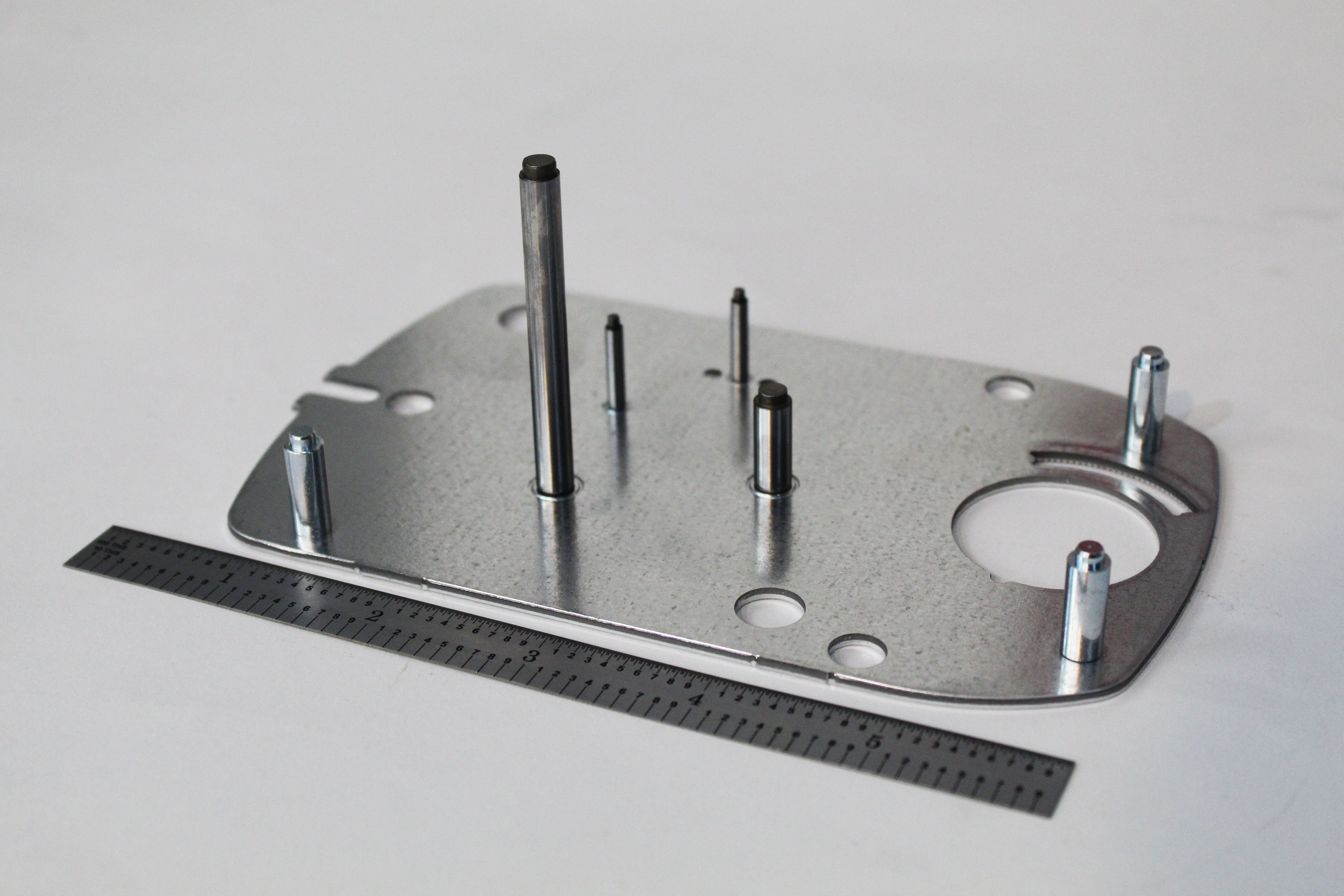

We run stampings up to .188” thick, but our specialty is high-volume, tight tolerance, precision stampings in a variety of materials from .003”-.060” thick. Our presses have full feed lines and are die sensor protection ready.

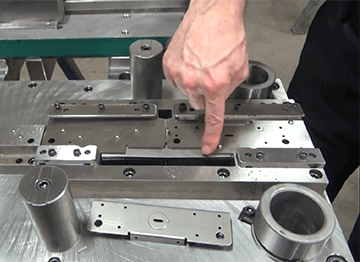

Our production stamping methods include progressive and single hit dies, using materials such as aluminum, brass, copper, bronze, carbon, stainless steels and exotic metals. We have expertise in progressive, deep draw, mandrel, blanking, cam dies, transfer, louvering, insertion and rolled seam dies, among others.

Our press capabilities range from 30 to 200 tons. Parts are fully inspected using vision systems, optical comparators, CMM equipment and functional gages.

WMPI serves a range of industries including aerospace, defense, medical and electronics, for applications such as heat transfer products, military components and electronic assemblies.

Customers Benefit from Using Our Custom Metal Stamping Services:

- In-house tooling, gage and fixture building

- As experts in carbide, WMPI has increased the run times of many of our tools between sharpening. This saves you money on die maintenance and part costs

- Full PM program for our equipment and tooling

- Inspection processes capable of first article, PPAP, collecting CPK data, lot controlling and functional checks

- Just in time and Kan Ban inventory processes insure on time delivery

Metal Stamping Solutions for Every Situation

For over 30 years, Wisconsin Metal Parts, Inc. has built a business based on listening to our client's needs and finding creative solutions to ensure they get the perfect parts for the job, with a guarantee of the highest quality and satisfaction...on time.

We have the equipment and skills at our service to get the job done for a wide variety of quantities and parameters.

Types of custom metal stamping services we offer:

- Prototype stampings

- Production metal stamping

- High-speed metal stamping

- Precision metal stamping

- Progressive die stamping

- High quality, complex, tight tolerance stamping

- Low-volume prototypes to high-volume progressive dies

Photo Gallery

Photo Gallery Capabilities

Capabilities Videos

Videos Quality Management

Quality Management