What is a Progressive Die?

What is Progressive Stamping?

Progressive stamping is a manufacturing process typically used for high volumes of parts. Parts are made by feeding material into a progressive stamping die that is loaded in to a stamping press. The material is fed a specifically designed distance or “progression” through each station of a stamping die, resulting in a finished part coming off of that die. There are many different operations that a die can perform such as trimming, forming, coining and adding in hardware, in-die tapping, to name a few.

For a live example of how a progressive stamping die works click here to see our video.

Each tool is designed to make a specific part, but sometimes there can be interchangeable elements in the die that allows it to make a series of parts. For higher

Progressive stamping is incredibly versatile and can make all sorts of parts. Each die is unique to the part and incredibly precise. Here are a few examples of some different levels of progressive die complexity.

Examples of a Progressive Stamping Die

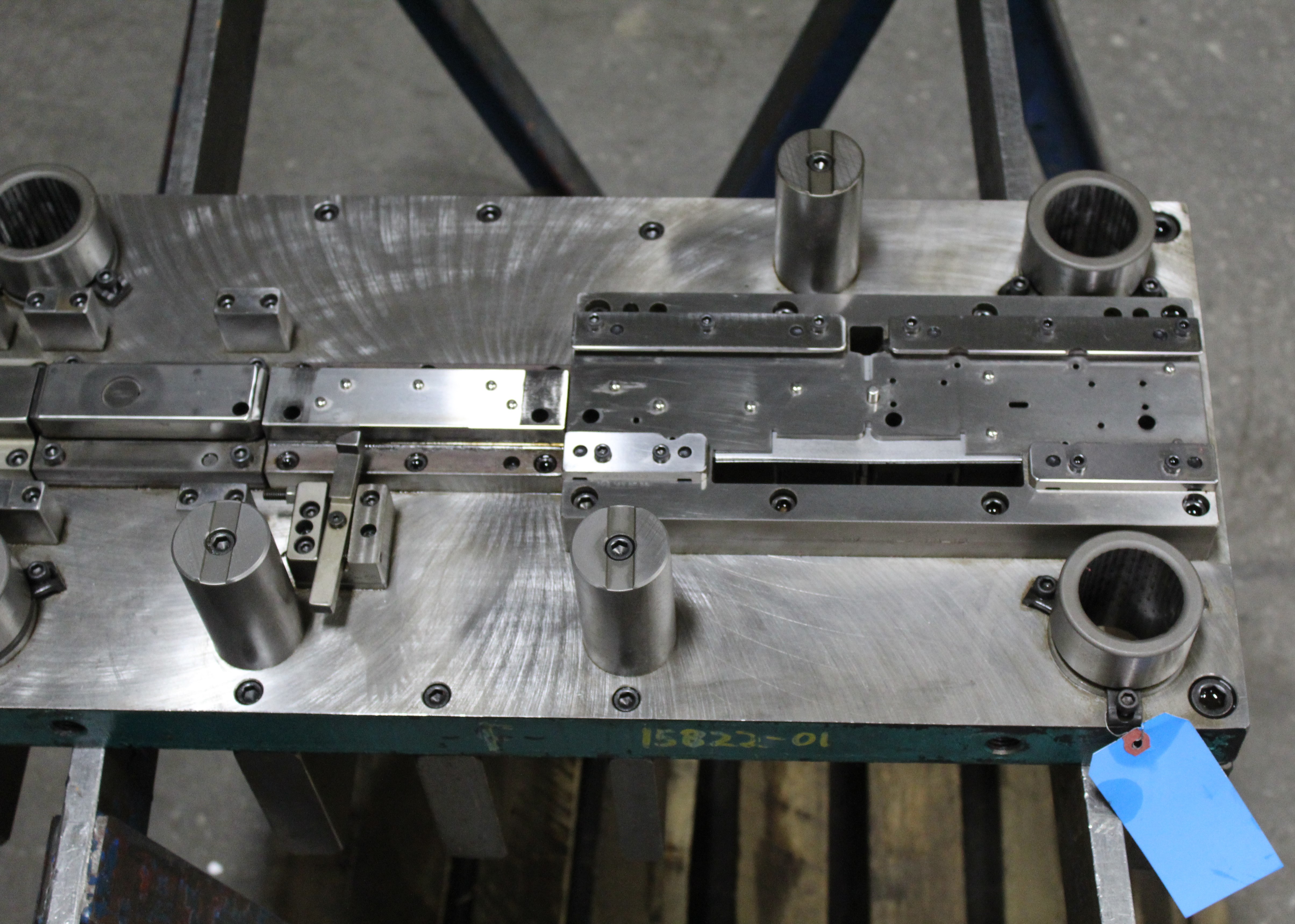

This example is showing a more economical progressive stamping die. While it is still a quality tool, it was designed to run lower volumes of this part. The die blocks are made of one piece and not inserted. This is a more economical way to build a die but can prove to be expensive if components need to be repaired, replaced or re-designed.

For a live example of this economic progressive stamping die click here to see our video.

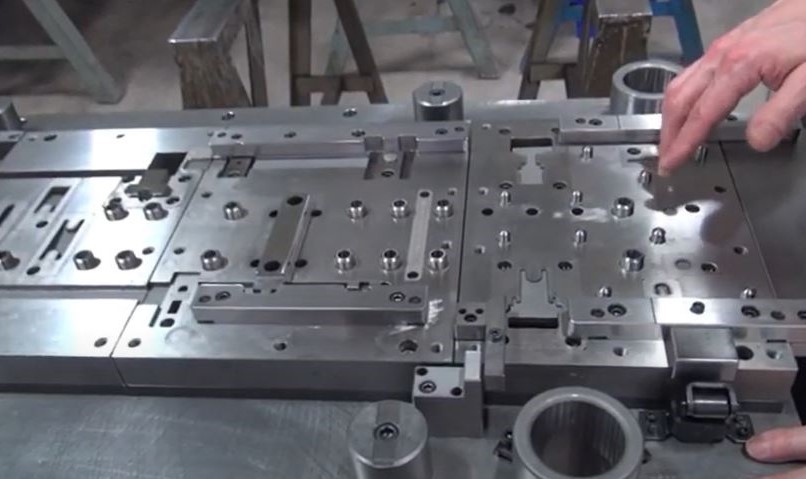

This example is showing a progressive stamping die that is meant to run higher volumes of parts. Now we are getting into inserted die blocks that allow for maintenance wear items to be easily replaced. This example also has guided stripper plates and inserted punch holders. This is a more expensive tool that is meant for years of running quality parts while allowing the die maintenance department to keep spare components on hand for quick repairs.

For a live example of this economic progressive stamping die click here to see our video.

This example is showing a progressive stamping die that is meant to run higher volumes of parts. Now we are getting into inserted die blocks that allow for maintenance wear items to be easily replaced. This example also has guided stripper plates and inserted punch holders. This is a more expensive tool that is meant for years of running quality parts while allowing the die maintenance department to keep spare components on hand for quick repairs.

Trust Our Custom Metal Stamping Company

Matching your needs to the proper type of tooling is a job for a skilled engineering and estimating team. If you have a specific project you would like to review, you can submit it here or call us at 262-524-9100 and we will help you explore the options and spend your money wisely.

At