Experience Our Wire EDM Department!

What is Wire EDM?

Wire Electrical Discharge Machining is a manufacturing process where a very thin wire (.003-.012”) uses an electrical charge to cut through materials that conduct electricity.

Some of these materials include aluminum, copper, steel, brass, tungsten carbide and even hardened tool steel! In Wire EDM, the wire does not actually touch the material, instead it has an electrical charge that does the cutting by causing erosion of the material through heat and flushing. This allows for an efficient method of creating very detailed and complex parts.

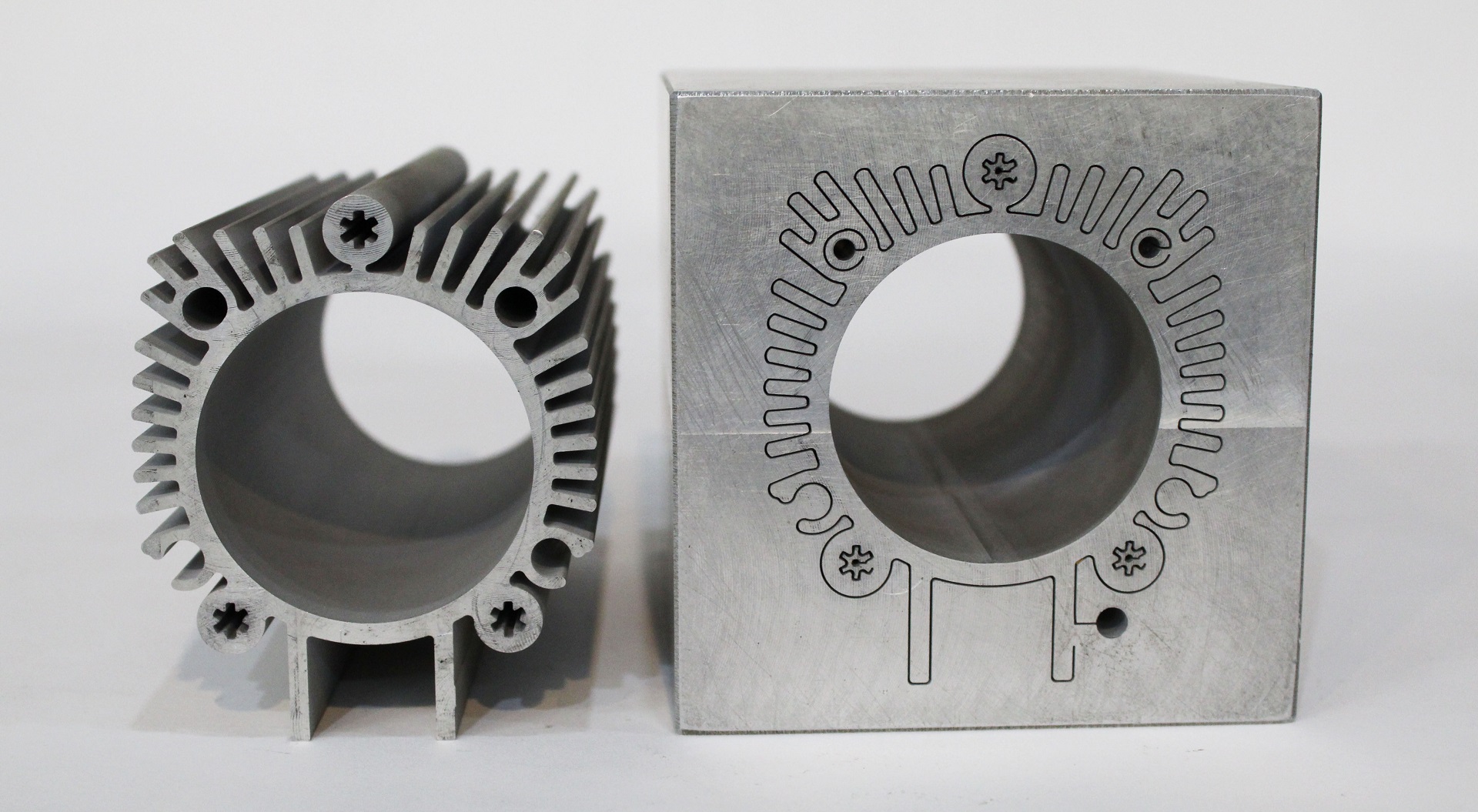

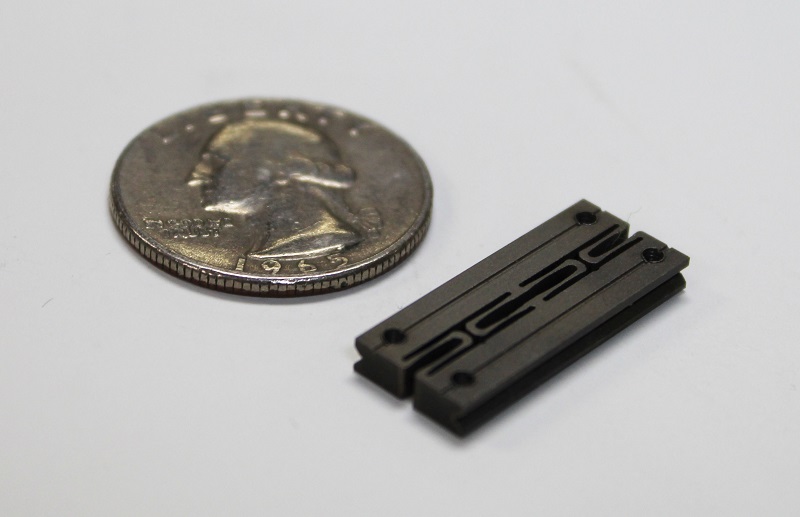

Using a start hole in the material, the wire is fed through the hole, and the electricity that passes through the wire will erode the material allowing us to recreate your CAD geometry. We can burn straight or tapered geometry using 4-axes. This process often takes place with both the wire and material being submerged underneath water, which helps control the sparking and flushes the debris out. Here is a good example of a complex piece we were able to create from a detailed CAD file:

After the initial rough cut, the machine is able to make ‘skim passes’ over the surface of the final shape. The more skim passes, the greater the accuracy and finish. However, cost will typically increase with the number of skim passes needed on a part. Tolerances on your part print will drive what is required for the WEDM process. Check out this video for a more detailed explanation of Wire EDM and how Wisconsin Metal Parts utilizes this machining process.

How can this department serve you best?

A strong and experienced Wire EDM department is able to produce efficient, quality work. A lot of people prefer Wire EDM for complex, detailed, high-tolerance work that goes into projects like dies and unique molds. It is also preferable for machining hard materials, which usually require intense processing. Wire EDM allows for machining without that pressure, impact or stress on the material, so long as the material is electrically conductive. This style of machining is also great for small runs, or parts that require a fast processing time! The ability to complete machining in one process leads to a fast turnaround and saves you money!

Beauty in the details…

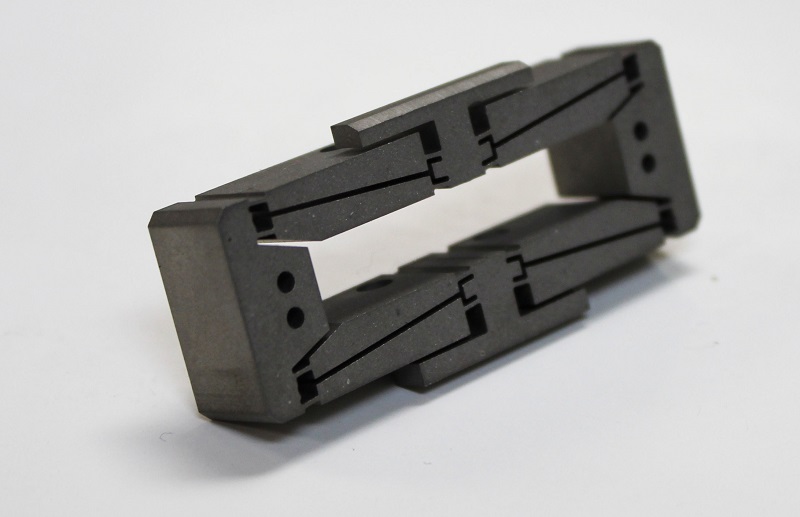

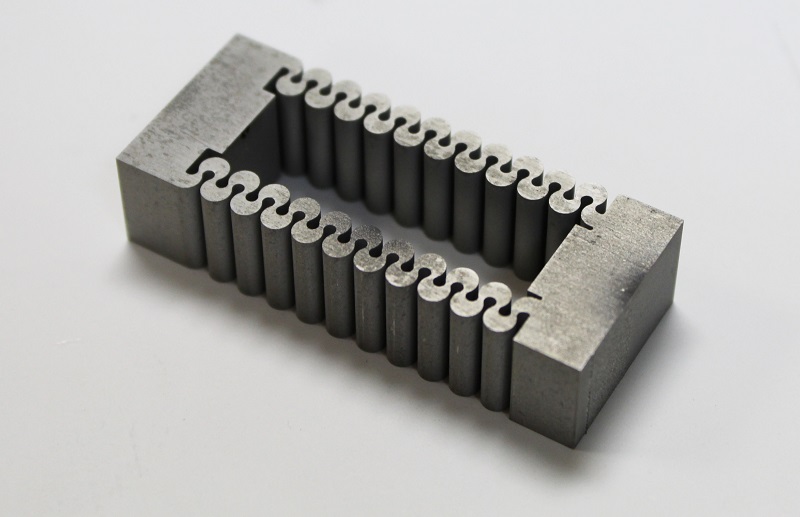

Here are some examples of the detail that is possible through Wire EDM work

Are you interested in manufacturing using Wire EDM? Wisconsin Metal Parts can provide a quick, efficient and cost-effective solution to suit many deadlines and budgets. Reach out today to talk to our experienced staff to see how we can serve you!