Experience Our Stamping Department

Sept 11, 2020

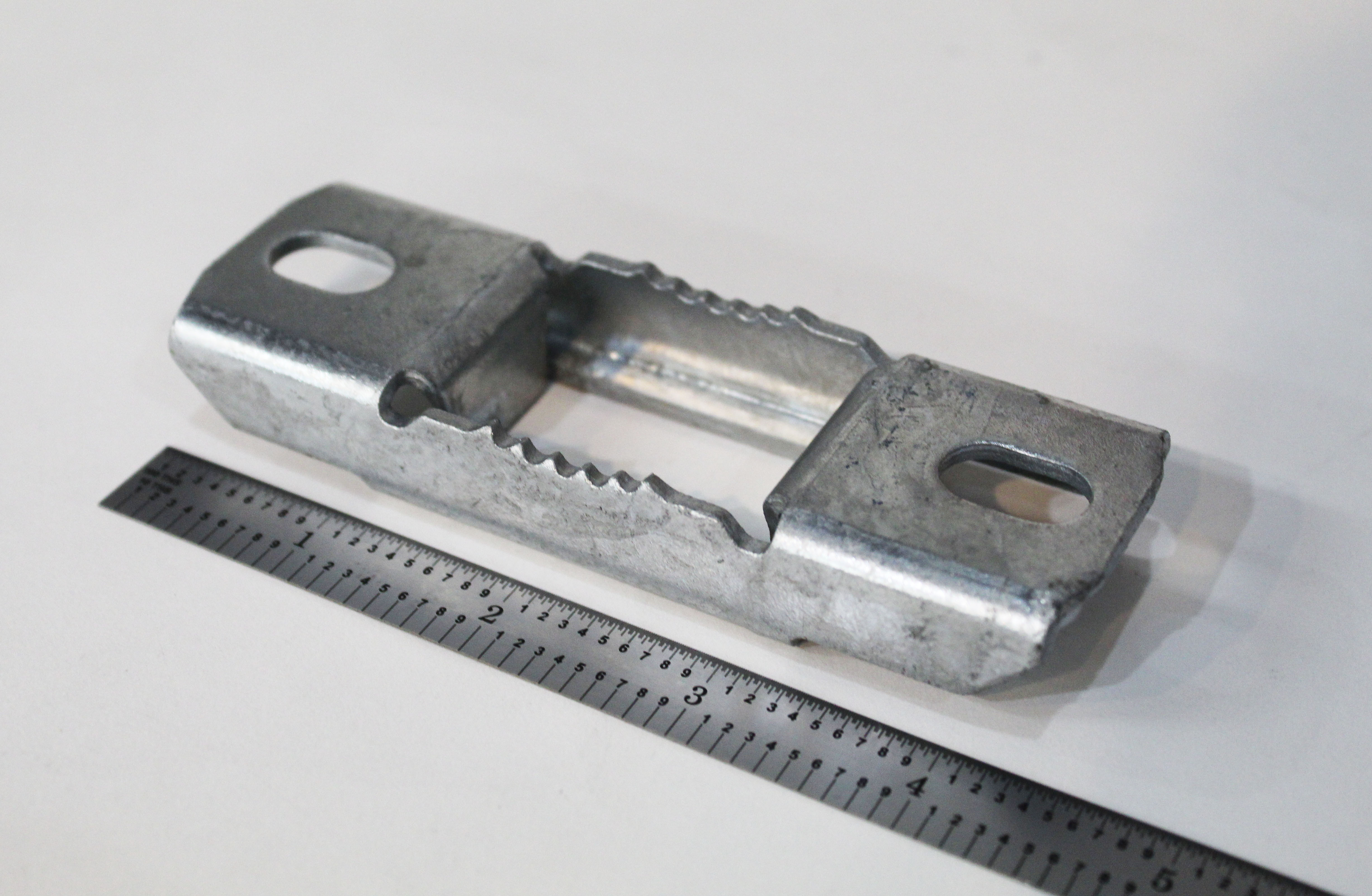

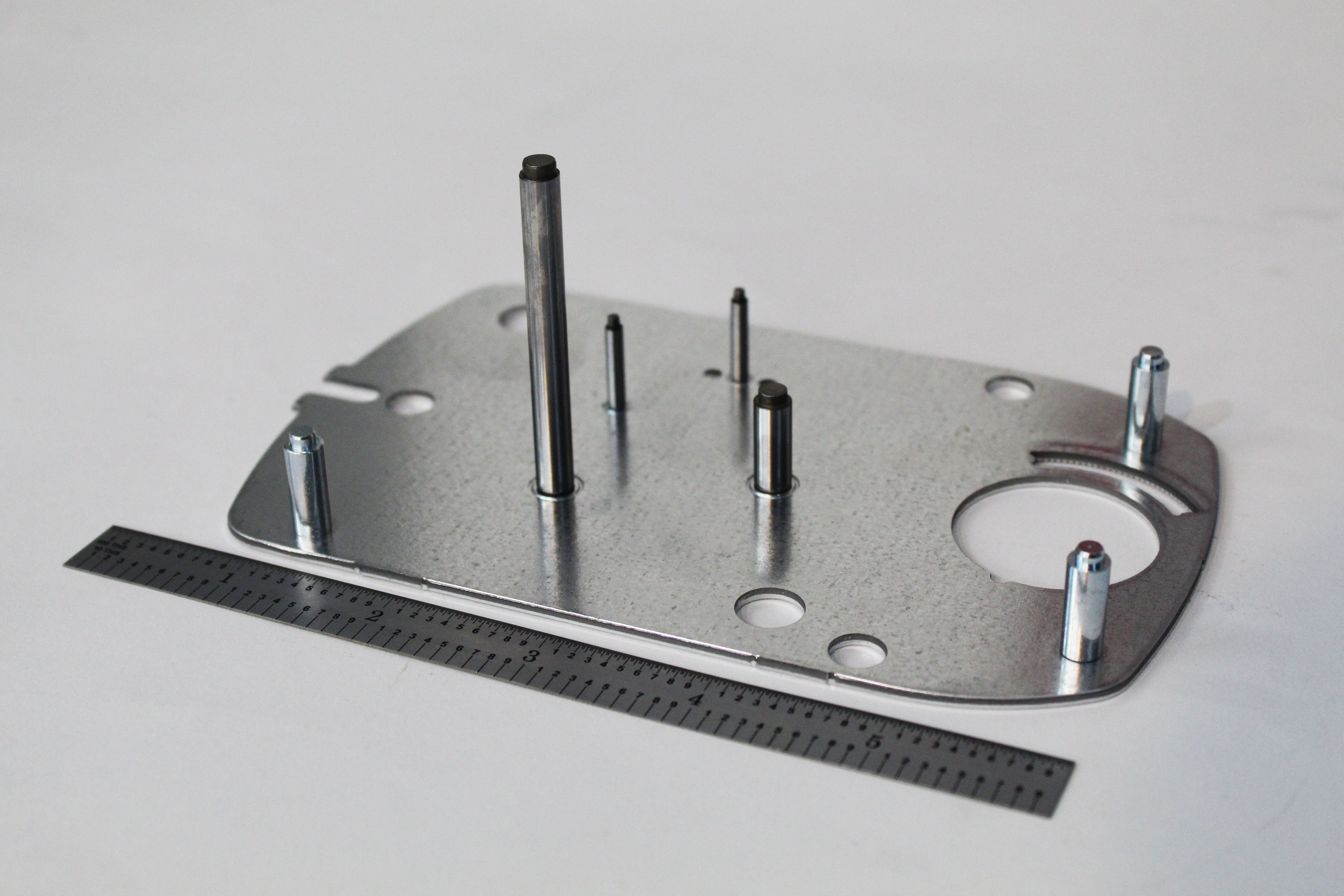

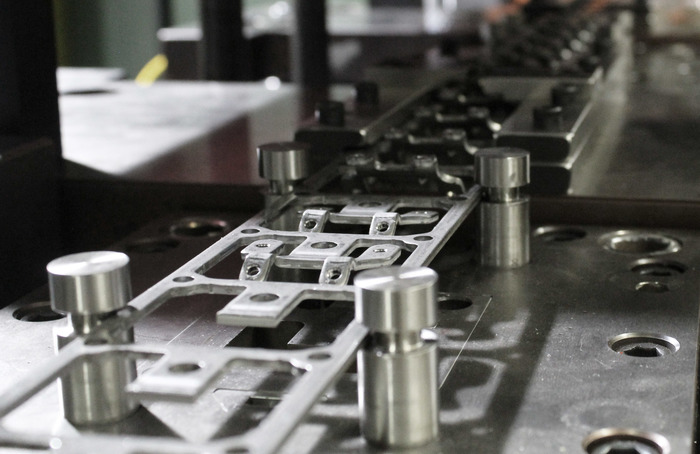

Metal stamping is a cost-effective solution for high-quantity metal manufacturing. The process involves a custom stamping die, developed for the specific part that is being manufactured. These dies then cold-form metal sheets into specific shapes. There are multiple types of stamping dies, and various forming techniques in each die, such as punching, embossing, bending, flanging and more.

Once the initial tooling is complete, the stamping operations allow a manufacturer to run higher volumes of a unique piece at a very competitive price. Many everyday items are made through this process, like washers and electrical plugs, but complex and detailed dies can manufacture millions of identical special parts. Stamped parts can be found in cars, hospital equipment, everyday household items, appliances, and even in space!

How Can this Department Serve You Best?

Wisconsin Metal Parts, Inc. provides metal stamping services to many industries. We run stampings up to .250” thick, but our specialty is high-volume, tight tolerance, precision stampings in a variety of materials from .003”-.060” thick. Our press capacity ranges from 30 to 200 tons and we can handle materials up to 18” wide. We run nearly 60 million stampings per year at a 98% on-time delivery rate. Our experienced toolroom is able to design, build and service dies that come through our presses which ensures quality stampings! We even have design simulation software that can help identify problem areas during your engineering process, saving you time and money while getting your products to market.

Take a Tour of our Stamping Department!

Check out some successes!

A wide variety of customers and industries have found success with the Wisconsin Metal Parts Stamping Department! Check out some of the great sample projects below!