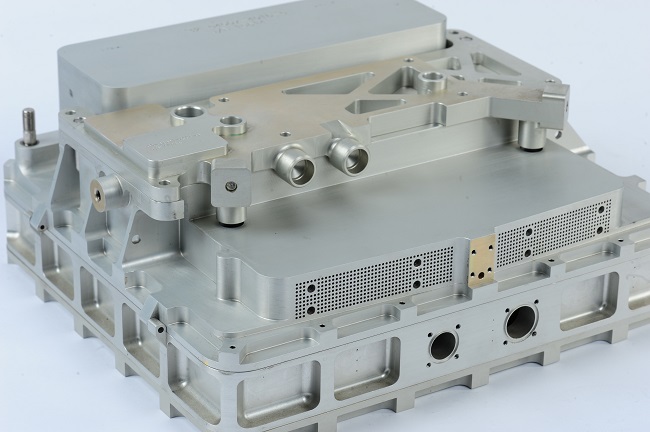

Complex Aluminum Casting Machining

Our die cast customer came to us needing support to machine their tighter tolerance, more complex work. They had previously machined these parts in-house but were challenged to keep a workforce skilled enough to run these more complex parts. WMPI moved the existing fixtures into our tool room and inspected them. We found that some repairs and modifications were needed to once again make parts to print. We were then able to conduct a Level 3 PPAP and get world-class quality parts into production.

WMPI has continued to run these parts for several years without any major quality issues. We have consistently achieved 98% on-time delivery for this customer with no non-conforming part returns. These parts involve milling, drilling, port tools, tapping and part washing. Parts are also inspected and separated for porosity issues.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description | Aluminum pump housing casting | |

| Capabilities Applied/Processes |

|

|

| Equipment Used to Manufacture Part |

|

|

| Overall Part Dimensions | 4.0 x 10.0 x 12.0” | |

| Tightest Tolerances | .0005” | |

| Material Used | Aluminum | |

| Max Material Finish | 125 | |

| In Process Testing/Inspection Performed |

|

|

| Estimated Part Weight | 3lb | |

| Industry for Use | Off-Highway Equipment | |

| Volume | 3,000 | |

| Delivery Location | USA |