Re-Sourcing Metal Stampings:

How to have a seamless transition

Unfortunately, there are times when you have to move on from a current supplier. Maybe your volumes got too high for them to handle, too low for them to be profitable, there is a dip in overall quality, or they just told you they are closing down. Maybe it is as simple as diversifying your vendor base more. Regardless of the circumstances, making changes during production can seem intimidating and set you up for supply chain delays.

There are three big topics to consider before a stamping takeover:

the old vendor, the new vendor and the tooling. Each topic is crucial to making the right move as efficiently as possible.

Let’s begin with reviewing the current vendor, or the vendor you are moving away from. It is important to review the issues you had with this company so you can ensure that they will not continue with the new supplier. Think about the reason(s) you chose to leave. What can you emphasize and communicate to your new potential vendor so the same problems do not continue?

Here are some common issues and reasons people leave a vendor:

- Quality they cannot solve: Some companies do not have the resources to solve quality issues. Could be a lack of technology for proper inspection or could be a lack of expertise to solve problems in maintaining tooling or running the parts.

- Financial stability: Economic pressures have challenged many manufacturers to stay in business, let alone invest in new technology to keep you competitive. Companies being sold, leadership changes or key employees retiring are other areas that should raise concern.

- Delivery times they cannot improve: If your vendor is repeatedly late in delivering and is constantly updating you with bad news that delays your project, it may be time to look elsewhere. This can be a sign that you are not a high priority or that their processes may not be as efficient as possible.

- You are not feeling important/prioritized: If you need emergency parts or a special accommodation, is your vendor willing and able to help you out? Do you feel like your emails and requests always get lost in their mailbox? Are your vendor’s top priorities to keep you competitive and find a way to support you?

- New guidelines they are not willing to update to: On some occasions, vendors are unwilling or unable to update their technology, equipment, processes or Quality Department in order to meet your markets new demands.

Next, there are aspects of your new supplier that you want to evaluate as well. Make sure to communicate to them about your current process and standards. A good vendor will look for ways to improve your process and save you money if there are changes that can be made.

Here are some things to consider:

- Tooling support: Does this supplier have the experience to troubleshoot, make changes and maintain your tooling? Are they currently running similar parts or processes? Do they have a tool room in-house?

- Quality department and processes: What quality systems does your new vendor have in place and what documentation can they supply you with? (PPAP, FAIR, etc.) Can they build inspection gages in-house for your parts or would you have to outsource those?

- Value beyond price: A strong partner wants you to succeed just as much as them, and will want to offer engineering support, CI ideas and ensure the quality of your parts all while focusing on keeping you competitive in your markets. Are they investing in new technology?

- Timeline: How long will it take them to get up and running? Will the tooling fit in their equipment? If not, can they make changes in-house? Can the current supplier run far enough ahead so the new supplier has time to get up and running without shutting down your production?

- Volumes: Does the new supplier have options to supplement immediate needs during the takeover such as laser cutting or CNC punching? Are they able to handle volume increases should they arise?

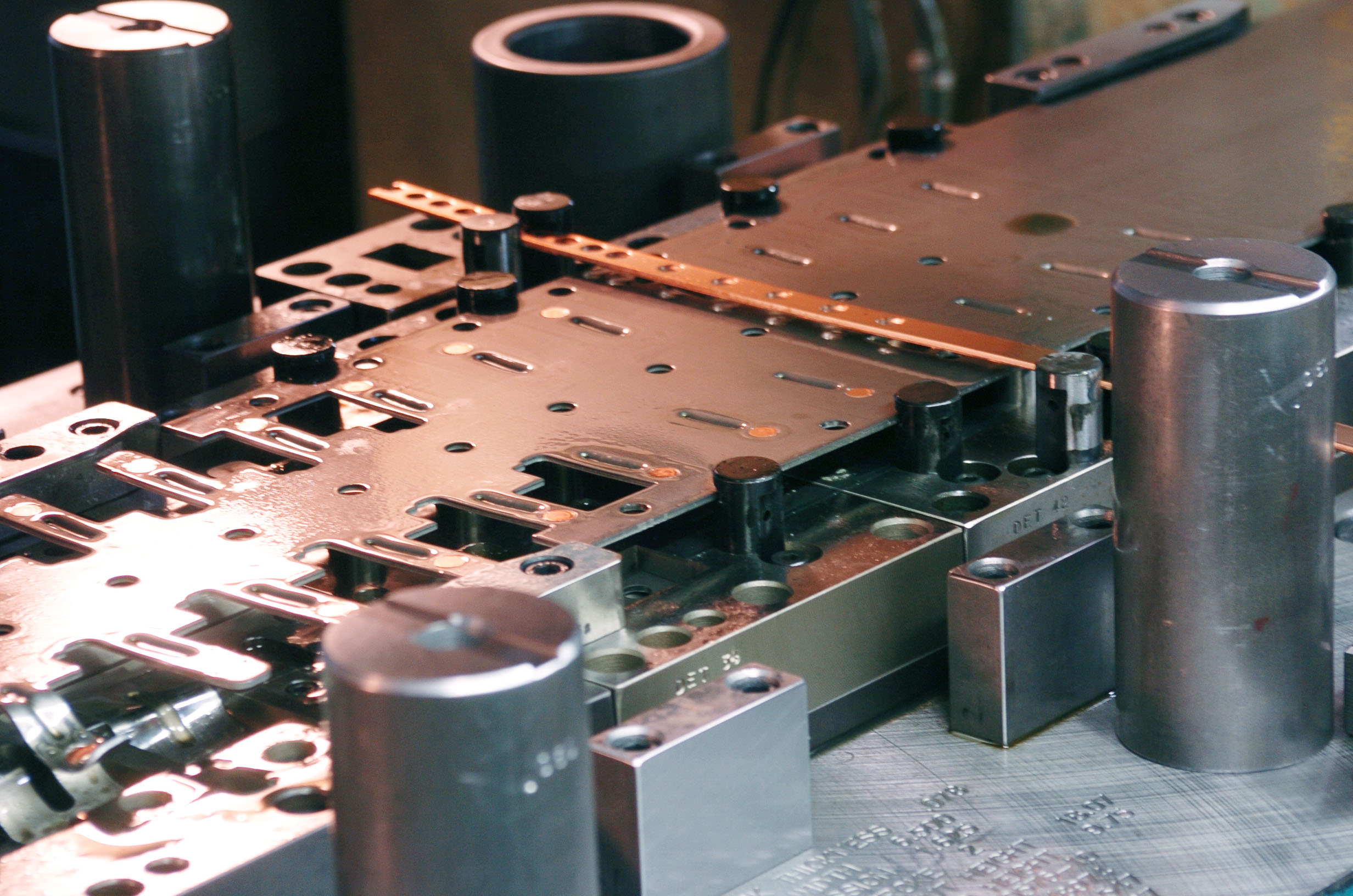

Finally, you need to consider the tooling, which is the most important aspect of a takeover. You don’t want to switch to a new vendor without fully analyzing your tooling and what it will take to transfer it over to them.

Here are some important considerations:

- Do you own the tooling and would your new vendor be able to use it to run parts?

- Do you have current designs or pictures, full die or components in a master die set?

- Can you purchase the current tooling if you don’t own it?

- Is the current tool making good parts per your part print?

- EAU, volume, type of tool, material info, width/progression, tonnage, target price

Communication is the key to a successful stamping takeover. Being clear about the timeline, expectations and standards will allow for a smooth transition. Make sure you have enough information in order to get a quote or budget for the project.

What is needed to get an accurate quote?

- Annual part volumes

- Type of tooling (progressive, single hit, etc..)

- Coil strip width and tool progression so material usage can be calculated

- Any special features or areas of concern

This should be enough info for a supplier to get some part costing together, subject to the assumptions that were made due to missing info in the quoting phase. However, there are some issues that can hinder an accurate quote.

Sticky Points

- You do not own tooling or your current tooling is in disrepair

- Current tool does not make parts to print

- Current vendor is not willing to run parts ahead to minimize delivery disruption

What if you do not have any of this information but you still need help? Try asking your prospective vendor how they have handled similar situations in the past. If they are going to have any chance of helping you make a smooth transition, they should be able to convey a game plan to you.

If you would like our help resourcing your stamping please contact us at wisconsinmetalparts.com or call us at 262-524-9100. We are here to help you remain competitive and spend your money wisely.

At Wisconsin Metal Parts we welcome challenges!