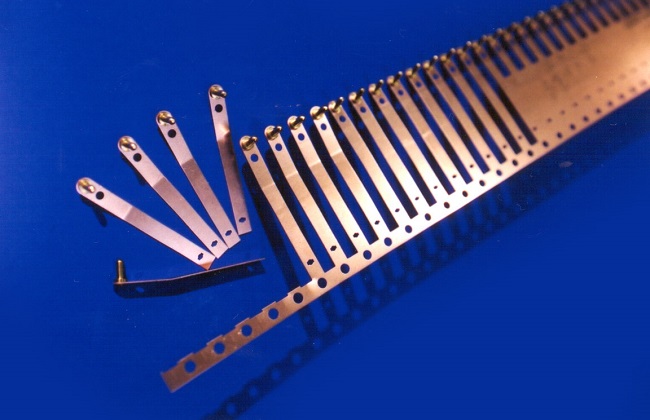

Electrical Contact with In-Die Insertion

We built a progressive stamping die complete with in-die pin insertion to efficiently make these electrical contacts. The pins are bowl fed and staked in place during the production run of the die. This tool is also capable of leaving the contacts attached to the strip to facilitate our customer's secondary operations. All tooling was built and run here at Wisconsin Metal Parts.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description |

|

||

| Capabilities Applied/Processes |

|

||

| Equipment Used to Manufacture Part |

|

||

| Overall Part Dimensions |

|

||

| Tightest Tolerances |

|

||

| Material Used | Copper | ||

| Max Material Finish | 32Ra | ||

| In Process Testing/Inspection Performed | First Article | ||

| Estimated Part Weight | < 1 lb. | ||

| Industry for Use | Automotive | ||

| Volume | 250,000 | ||

| Delivery Location | Midwest, USA | ||

| Standards Met |

Customer supplied print, 2D CAD Drawing, 3D model MIL specifications Material certifications |

||

| Product Name | Electrical Contact |