Prototyping and Reverse Engineering Services

Prototyping

Wisconsin Metal Parts, Inc. provides pre-production prototypes for your functional testing. With our well-equipped manufacturing systems, we can make your prototypes using laser cutting, machining or die-struck parts, depending on your needs. Our stock tooling may also give you better value. All of this is performed in-house.

We look at proto-types in two categories. The first would be made by using the same methods as the planned production process. This typically costs more as it is more tooling intense to replicate the production method. The second option is to make the parts using whatever method is needed to make you a dimensionally correct part. We have options such as Wire EDM, Fiber Laser, CNC Punching and CNC Machining to give you the best parts while keeping costs at a minimum. We also utilize soft tooling and share modular tooling to keep tooling costs in check. Let’s take a look at your specific project needs and come up with an appropriate game plan.

Reverse Engineering

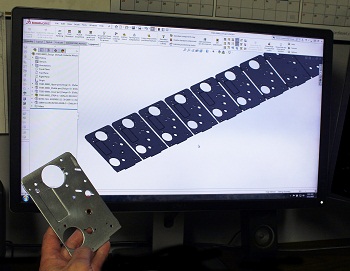

Have a part but do not have drawings? We also provide reverse engineering services on metal parts including castings, stampings and sub-assemblies. We have successfully helped industrial clients with metal part re-creation when replacement parts are not available. WMPI can also take a metal fabrication and create all the component prints for future production when original drawings are unavailable. In those cases, inspection can be performed and a replica part can be created as a Solidworks model. From there we can pick the best method to replicate your part.

We typically get reverse engineering requests to replace damaged parts that are unique to a machine or tool. WMPI can utilize any combination of CNC Machining, Fiber Laser, CNC Brake, Welding, Wire EDM and Tool Room capabilities to recreate your part. We also need to be mindful of copyright and patent laws when replicating components.

Frequently Asked Questions about Prototyping & Reverse Engineering

Proto-types can prove out a challenging process before a production tool is made. They can also be used as samples for product testing or test fitting into larger assemblies. Often times the costs of a proto-type can be recovered in less costs to develop a production tool and shorter lead times to build the production tooling.

Inspection is driven by customer requirements, keeping quality and costs in balance. Typically a First Article is requested where all of the dimensions on your part print are measured and verified on an inspection report. Another option is to simply define the critical dimensions that are to be held thereby reducing the amount of inspection needed.

We would use a variety of inspection equipment including; CMM, Vision System, Laser Scanner and hand held measuring instruments to determine the size of the part and location of features. From there our design team would draw the part and create a model useable for manufacturing. Often times the most difficult part is defining what features are critical for the function of the part.

That will vary depending on the specific project and if the part needs to be replicated exactly or if we can make some cost savings improvements. We normally like to start the discussion finding out what the part is used for and the intended function? A sample part and seeing it in action is helpful.

We have partners that can perform material analysis from a small sampling of the parent material.

Photo Gallery

Photo Gallery Capabilities

Capabilities Videos

Videos Quality Management

Quality Management