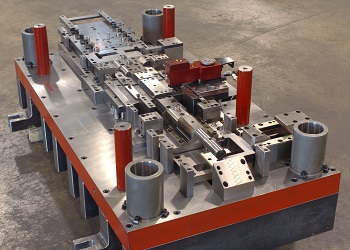

Progressive In-Die Tapping

Our customer came to us looking for ideas to hit their target pricing on a stamped Flange. After review with their engineering team, we designed and built this progressive stamping tool with an in-die tapping unit to add a threaded hole during the run. With this tapping unit, Wisconsin Metal Parts eliminated a secondary operation allowing them to save $.25 on their overall part cost. The tapping unit added an additional $12,000 to the die build. With their volumes near 100,000 pieces annually this was a good ROI for our customer and quickly paid for itself.

To learn more about this project, including tolerances and inspection processes, please contact us today or see the table below.

Project Details

| Product Description |

|

||

| Capabilities Applied/Processes |

|

||

| Equipment Used to Manufacture Part | Solidworks, WEDM, Jig grinding, CNC form grinding, CNC machines | ||

| Equipment Used to Manufacture Part | Solidworks, WEDM, Jig grinding, CNC form grinding, CNC machines | ||

| Equipment Used to Manufacture Part | Length: 26" Width: 42" |

||

| Tightest Tolerances | ±.0005” | ||

| Material Used | A-2, D-2, M-2, CPM, 4140, Carbon Steel | ||

| Max Material Finish | 125Ra | ||

| In Process Testing/Inspection Performed | First Article, CMM, Inspection Gage, 500 piece runoff | ||

| Lead Time | 13 Weeks | ||

| Industry for Use | Automotive | ||

| Volume | Tooling designed to run 800,000 hits | ||

| Delivery Location | Midwest, USA | ||

| Standards Met | Customer supplied print, 2D CAD Drawing, customer die standards, First Article approval, runoff | ||

| Product Name |

Progressive Die with In-Die Tapping |