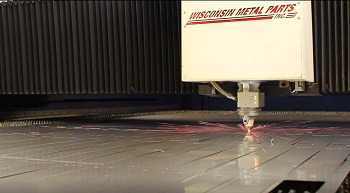

Fiber Laser Cutting Services - Prototype to Production

What is Fiber Laser Cutting?

Fiber Laser Cutting is a process where banks of diodes create light that is channeled and amplified through a fiber optic cable. Once amplified, the light is straightened/collimated and focused by a lens onto the material to be cut. Creating this light makes fiber lasers much more efficient than CO2 lasers. Fiber lasers are more electrically efficient, have less maintenance costs and allow for higher speeds as well.

What can we do for you?

Wisconsin Metal Parts has one of the fastest lasers in the industry ready to serve you. We can cut your metal parts amazingly fast and accurately. As one of a select few metal part manufacturers in Wisconsin with on-site fiber laser cutting and laser marking services, WMPI can produce small, intricate pieces or larger items up to 10 feet long.

We offer fiber laser cutting and marking as stand-alone services, or as time- and cost-saving steps among our secondary manufacturing processes. Our staff have specialized training in fiber laser technology, plus decades of experience processing stainless steel, brass, copper and other metals. Other services include pre-production prototypes, reverse engineering, engineering/design and in-house tool, gage and fixture building.

Compare Our Speed to Your Laser

- Stainless at 1320 in/min with nitrogen

- Steel at 1300 in/min with nitrogen

- Aluminum at 750 in/min with nitrogen

- Aluminum at 1722 in/min with oxygen

- Copper at 787 in/min with oxygen

- Brass at 827 in/min with nitrogen

Frequently Asked Questions about Fiber Laser Cutting

Although our lasers can process thicker material, our optimal thickness in steel & stainless steel is 0.060”.

We also can process aluminum up to ¾” and copper up to 3/16” thick. We have cut up to 1” Steel but prefer the cut off to be 3/8”

Steel, Galvanized Steel, Stainless Steel, Aluminum, Copper, Brass, Treadplate, Aluminized, Perforated, Rigidized, Carbon Fiber, Tungsten and Titanium.

Each type of laser has benefits. Our 5K fiber lasers are 2-3x faster than a C02 laser in materials .25” or thinner with a superior edge condition. A C02 laser can cut thicker materials more efficiently. The fiber laser can also cut highly reflective materials. Cutting reflective material on a C02 laser can cause premature wear of the mirrors that guide the beam. A fiber laser does not have mirrors and relies on a fiber optic cable to deliver the beam.

We have agreements in place where we process and ship orders within 3 days. Others might take 2-4 weeks. It depends on the materials needed and if there is any painting or plating involved. With some good planning we can work out a delivery schedule that meets your needs.

We can do low volume prototyping, usually as pre-production runs. However, repetitive volume is what fits our equipment best since everything is CNC controlled and we have material handling automation.

While this takes slightly longer to set up, we make up for it with speed and repetitive accuracy.

Yes, we have cut perforated material and expanded metals before. While it is not the most efficient, it can be done.

We do not cut plastic or wood with our lasers due to the fire hazard involved when also processing metals.

We have several CMM's, including a Romer Arm. We also have a Virtek Laser Scanner that quickly inspects flat patterns in a matter of seconds.

Photo Gallery

Photo Gallery Capabilities

Capabilities Videos

Videos Quality Management

Quality Management