Wire Electrical Discharge Machining (WEDM) Services

What is Wire EDM?

Wire Electrical Discharge Machining is a manufacturing process where a very thin wire (.003-.012”) uses an electrical charge to cut through materials that conduct electricity. In Wire EDM, the wire does not actually touch the material, instead it has an electrical charge that does the cutting by causing erosion of the material through heat and flushing. This allows for an efficient method of creating very detailed and complex parts.

What can we do for you?

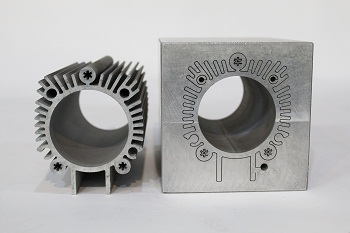

Working with any electrically conductive material up to 16” thick, Wisconsin Metal Parts, Inc. supplies wire electrical discharge machining (WEDM) services for parts such as die and mold components, nozzles, keyways and actuators. In addition to tool steels, we are experts at cutting carbide, have equipment dedicated to cutting that material and can run 24/7.

Capabilities

- 4-axis cutting: Parts up to 41.3” x 25.6” x 16.77” with a maximum weight of 1,763 lbs.

- Fine wire cutting can produce true shapes and corners down to .001” with a minimum wire diameter of .003”.

- Climate controlled Wire EDM Department that maintains tolerances as tight as ±.00005”.

- Specialists in building fine blank tooling.

- Small-hole EDM drilling from .013 - .120” diameter in hard or soft materials.

- Specializing in difficult-to-make parts and challenging components

- We build our own fixtures and produce surface finishes down to 4 Ra” for carbide and 8 Ra” in steel.

We Are Carbide Insert Experts: Click Here to Learn More

With Metal Stamping, Fabrication, CNC Machining and CNC Grinding WMPI can be a single source for your assembly and sub-assembly needs. Get us involved early and we will help you spend your money wisely.

Wire EDM – Continuing Education

Frequently Asked Questions about Wire EDM

Aluminum, steel, copper, bronze, tool steel (hardened or soft), carbide, or any material that can conduct electricity.

Lead times in our Wire EDM department can be as quick as a few days, depending on the project and material needed.

We can hold tolerances as tight as .00005”

Yes, we often make prototype parts prior to production being finalized. We also make a lot of tooling components through our toolroom using Wire EDM.

DXF, DWG, STEP, Solidworks

We have cut features into material as thin as foil and as thick as 16”

Our AGIE machines can handle .003-.012” wire

We can hold finishes as fine as 4 Ra” in carbide and 8 Ra” in tool steel.

Our small hole drilling machine can handle a .010” electrode that normally produces a .013” hole. If we need to do a precision finish on a hole, we would probably be in the .015-.017” range after Wire EDM.

Using .004” diameter wire we can cut a .0025” internal radius.

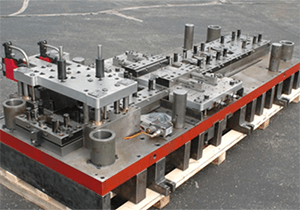

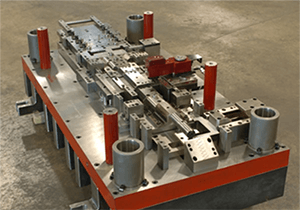

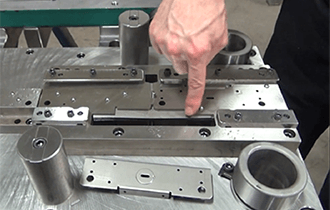

Photo Gallery

Photo Gallery Capabilities

Capabilities Videos

Videos Quality Management

Quality Management