PPAP: What is it and why do I need one?

June 15, 2020

What is a PPAP?

A Production Part Approval Process is a standardized process that helps manufacturers and suppliers communicate and approve production designs and processes before, during and after manufacture.

Why should I bother performing a PPAP?

This process will make sure that you and your manufacturer are on the same page. PPAP’s help ensure that the processes used to manufacture parts can be reproduced consistently. This sets some expectations for how PPAP’s must be performed. They must be run identically to the production process with production equipment and tooling, production employees and outputting at a production rate. Setting up the exact conditions the part will run in is crucial to getting a consistent output during the eventual production.

What’s up with the different PPAP submission levels?

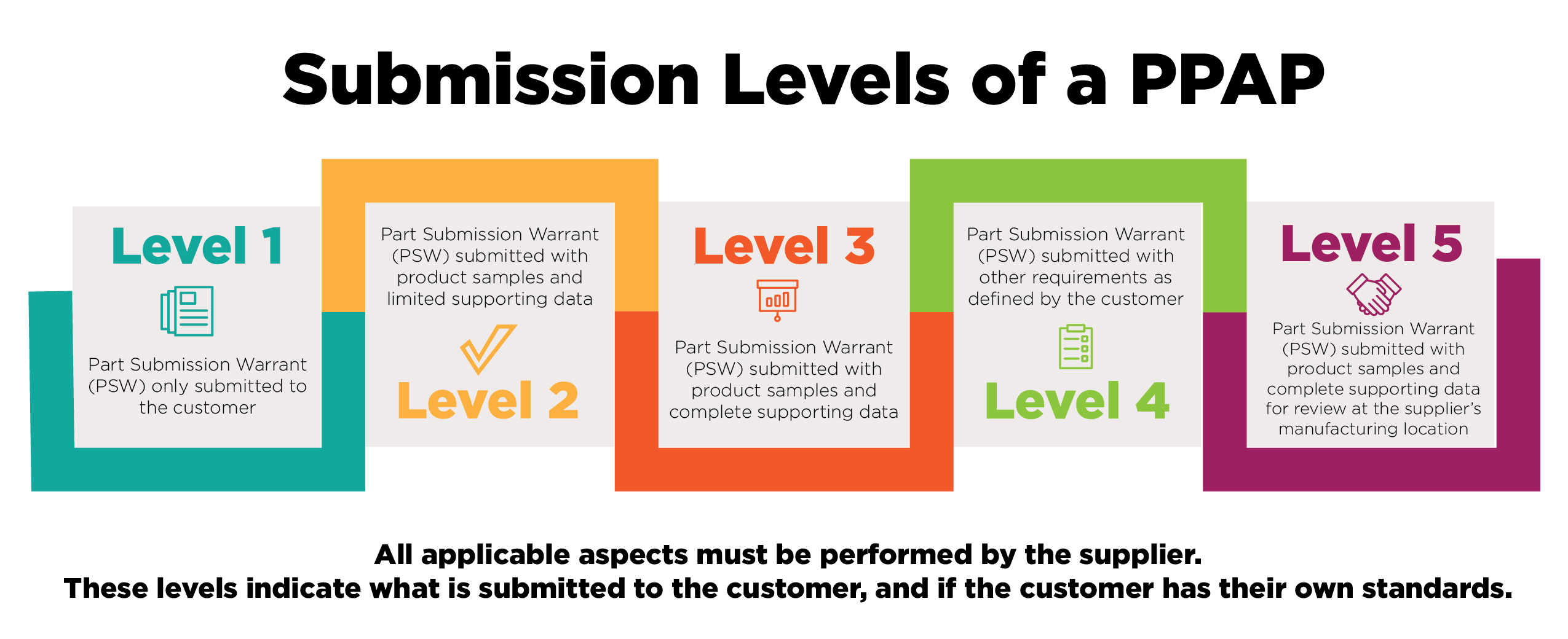

AIAG PPAPs specifically require five levels of submission. All applicable aspects must still be performed by the supplier. The levels just indicate what is submitted to the customer, and if the customer has their own standards, all applicable aspects may not be required. The submission levels are as follows:

Level 1 – Part Submission Warrant (PSW) only submitted to the customer

Level 2 – PSW with product samples and limited supporting data

Level 3 – PSW with product samples and complete supporting data

Level 4 – PSW and other requirements as defined by the customer

Level 5 – PSW with product samples and complete supporting data available for review at the supplier’s manufacturing location

Why is a PPAP negotiation necessary and when is a PPAP required?

PPAP’s are similar to a strategy or plan, and serve as the direct negotiation between customer and supplier to confirm how each element is satisfied. Not all PPAP’s are the same! Depending on the part and process, it can take considerably more or less time to complete the document. The longer it takes to develop the PPAP, the more costs are incurred by the supplier. Negotiation must take place before the requirement is accepted and the process is put into motion. This ensures that both parties are on the same page with their expectations.

PPAP’s are required under certain circumstances:

- During the first qualification run of a part

- Any time changes are made to a part, either by the you or the supplier

PPAP’s are also required annually, so if you are running the same part for years and years, this ensures that the process remains consistent. You may also request a new PPAP at any time during the life of the part or product.

What all is in a PPAP?

At first glance, this document can seem overwhelming with 18 total elements, but once you know what to look for, you can find all the information you need and more! Note that not all elements are in every PPAP depending on the parts and processes.

Here’s a brief summary on all 18 elements:

- Design Records: This includes ballooned prints and a copy of the latest drawing. This drawing will include print notes, standard tolerance notes and other crucial information about the design of the part.

- Engineering Change Documents: These documents will show detailed descriptions of any changes that were not included in the drawing.

- Customer Engineering Approval: This element goes hand in hand with an Engineered Change Document, as all of those elements need documented customer approval.

- Design FMEA: FMEA stands for Failure Mode and Effect Analysis. This element only applies if your supplier is responsible for the product design. If you are responsible for the design, the list of critical and high impact product characteristics should be shared with your supplier on the Process FMEA and Control Plan.

- Process Flow Diagrams: This element does exactly what it says- it describes the production process steps and sequence. It also includes incoming material components as well as subcontracting processes and elements.

- Process FMEA: The PFMEA follows the process flow steps and indicates what could go wrong during production and assembly of each component. This helps audit the process to determine potential shortcomings and issues when the part goes to production. Usually these issues are scored, and if the scores are too high, actions must be taken and documented in order to reduce the score and risk.

- Control Plan: This plan defines all of the methods used for process control and serves as a “game plan” for the production process. The control plan must minimally follow the PFMEA steps, and will provide more detail on how potential issues will be checked for in quality, assembly and final inspection of the part or product.

- Measurement System Analysis (MSA): Basically, this ensures that the quality measurement systems are accurate, precise and stable. This applies to any gages, measurement and test equipment. MSA commonly is testing for Gage Repeatability and Reliability, any bias, linearity, and stability.

- Dimensional Results: This element is a list of every dimension noted on the ballooned drawing and includes: Product characteristics, specifications, measurement results and assessments of certain dimensions. This can also include a First Article Inspection Report (FAIR), which documents the first 3-6 pieces produced.

- Material, Performance Test Results: These are the results from any tests that were specified in elements 1 and 7. It can also include material certifications from suppliers showing compliance for specifications on the Design Record or Control Plan.

- Initial Process Studies: This element includes all of the Statistical Process Control (SPC) charts that affect critical characteristics. The intent of these studies is to demonstrate that critical processes have stable variability and that running near the intended process is under control. If there are no CTQ’s, typically SPC is not required. If it is required, sometimes it must be monitored in real-time throughout the life of the product.

- Qualified Laboratory Doc: These are simply copies of all laboratory certifications from the labs that performed the tests to show that they are qualified. This includes lab scope and documents that all instruments used to measure/test the parts are calibrated and followed specific processes.

- Appearance Approval Report (AAR): The AAR is only applicable for components that have specific color, grain or surface appearance requirements. It ensures that these elements meet the customer standards.

- Sample Product: Parts are procured with the PPAP that follow the control plan and production process. The quantity of these parts is determined by the customer.

- Master Sample: This is also referred to as the “PPAP Retain.” This is the master part made under proper PPAP conditions that the supplier keeps.

- Checking Aids: This section details special tools for checking parts, shows images of the tool and calibration records. This usually includes any inspection fixtures or gages created for the PPAP.

- Records of Compliance: These are simply records of compliance to all applicable customer-specific requirements. Some of the common requirements are: RoHS, REACH, DFARS, Conflict Minerals, Proposition 65, WEE, MIL and more.

- Part Submission Warrant (PSW): This is the final form that summarizes the whole PPAP package. It gives the part info, the reason for submission, the level of documents submitted and asks for supplier notes on any deviations or if the PPAP cannot be submitted.