How to Create Quality Progressive Die Designs

March 18, 2019

Our latest discussion in our series about progressive dies explores the design process. We reconnected with Dave Holzer, Journeyman Tool and Die Maker and the Sales and Marketing Manager at Wisconsin Metal Parts.

Q. Dave, it’s great to talk with you again. When Wisconsin Metal Parts starts the design process for progressive stamping dies, what are some questions you ask?

Dave Holzer: We ask 8 questions that are essential for making a high-quality die design. First, we ask, ‘Can this part be made?’ Then we assess if the part can be made with a progressive die and evaluate whether a progressive die is the most cost-effective way to make the part.

Q. Does that mean you might sometimes say ‘no’ to designing a progressive die?

Dave Holzer: When we partner with customers, we look for the best way to make their part. There are alternatives to progressive dies. We focus on delivering high-quality, cost-effective solutions.

Q. Okay, those are the first 3 questions. What’s next?

Dave Holzer: After we determine that a progressive die is the best choice for the part, we start exploring the factors that affect our price quote for designing and building the die. We ask about tolerances, the dimensional accuracy that the customer requires from the part. We learn about the materials that will be used to make the part. The work material’s machineability will influence our decisions about the tool design. We also ask about the customer’s expectations of life expectancy of the die as we scope out the design.

Q. Tolerances, materials, and life expectancy – got it! And the last two questions?

Dave Holzer: Well, we always ask customers if they have internally created die design standards. We’ll incorporate those into the tool design. Finally, we’ll discuss any challenging areas of the tool design that we might want to prototype before we build hard-tooling for it.

Q. That’s helpful information for customers to know as they start the design process. What happens after you provide a quote?

Dave Holzer: When we receive a customer’s purchase order for the design, we’ll do a contract review. We’ll verify we have the most up-to-date drawings. Then, our designers will do a strip layout that’s shared back with the customer for approval. With the initial design completed, our team will do a full layout of the die, designing most of the components. The customer will approve this layout, too.

After that stage, our designer breaks out all components of the die into individual pieces. Component designs are shared with toolmakers to start the build process. If the customer wants to approve the components, we’ll set up time for review. We’ll always have an internal discussion where our design team and toolmakers review the die and components to make sure the tool will make the part as expected.

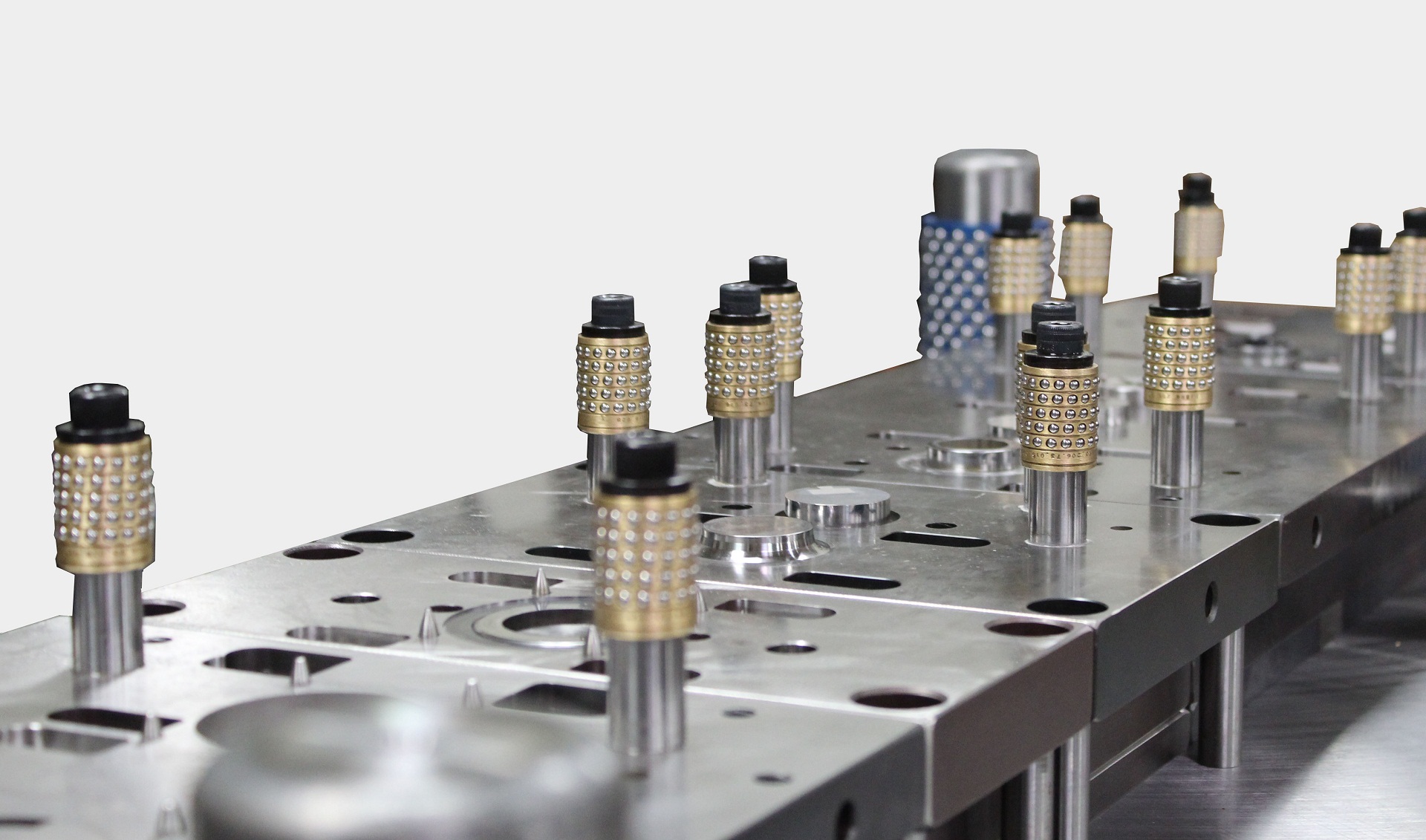

Then we build die part components, punch components, holders, die sets, die shoes, and any other components the customer needs based on the design criteria.

Q. So you have several touch points with the customer during the design phase?

Dave Holzer: Yes, we believe that consistent collaboration with customers is essential to building a quality die and meeting customer expectations.

Q. What kind of technologies do you use to create the die designs?

Dave Holzer: We have add-on software that we use with our design program. One program, Task Form, helps us determine if there are any areas where the material may tear, rip, or thin during forming. We also use Dr. ABE Blank to help us with round draw parts. The software identifies how many draw stations we’ll need to get enough part material during production. And we also use Logo Press, a great add-on to speed up the design process. We’ve invested in these technologies to reduce development cost and the final cost of the tooling.

Q: After the tool is built, what’s the next step in your process?

Dave Holzer: We’ll get feedback from our toolmakers, share it with our designers, and update our design to reflect any changes that happened on the shop floor. We’ll have a current design as a starting point if the customer wants to make changes or we need to make repairs.

Q. Thanks for your time today Dave. Any final thoughts you’d like to share?

Dave Holzer: At Wisconsin Metal Parts, we design, build and run progressive stamping dies, gauges, and fixtures. Send us your drawing, and we’ll come up with the most cost-effective solution to meet your needs.

If you’re interested in learning more about progressive dies, visit Wisconsin Metal Parts’ website to watch this series of educational videos.

For more information or to schedule a facility tour, contact the team online or call (262) 524-9100. We can set up a time to discuss your business needs and explore the best solutions.

Watch our video about quality progressive die designs below for more information.